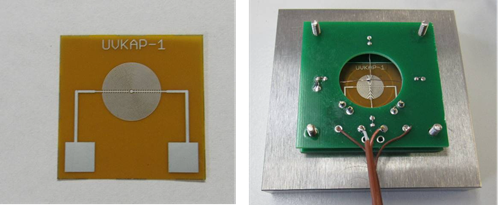

The UV Cure Sensor is a thin, cost-effective dielectric sensor tailored for examining UV-cured resins, prioritizing ease of use and affordability.

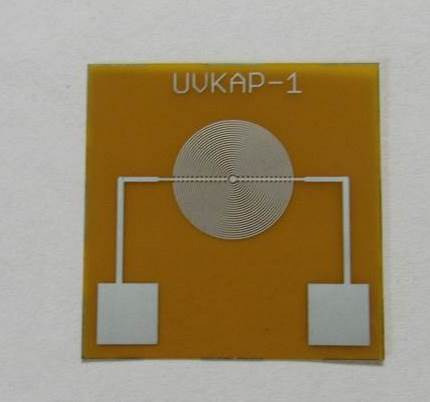

Constructed on a polyimide substrate, the sensor measures 2.45 cm (1.00”) square and is merely 100 µm (0.004”) thick. Its tin-plated electrodes boast widths and separations of 100 um (0.004”). Operating within approximately 100 µm (0.004”) of the electrodes, the UV Cure Sensor gauges the dielectric/conductive characteristics of materials, facilitating cure monitoring beneath a thin resin layer beyond the surface and the oxygen inhibition region.

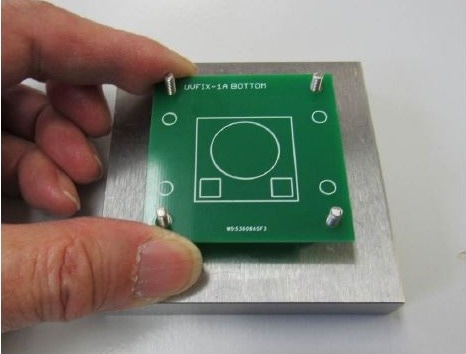

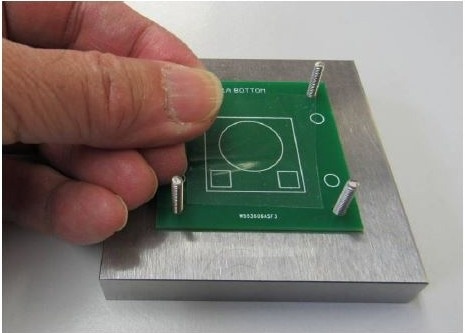

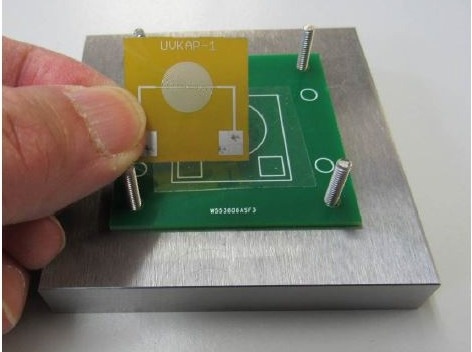

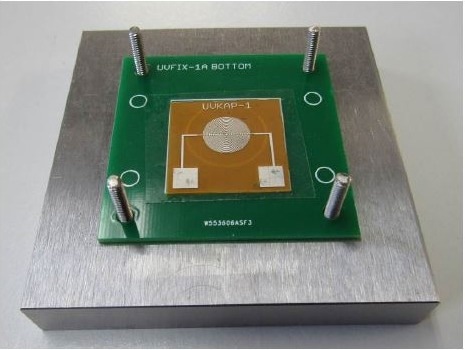

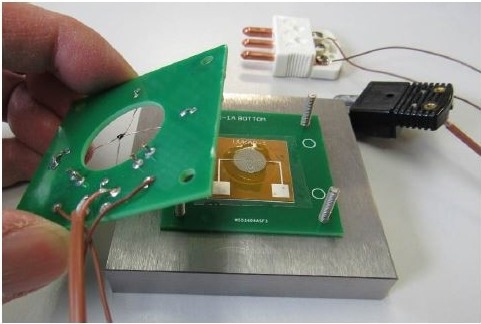

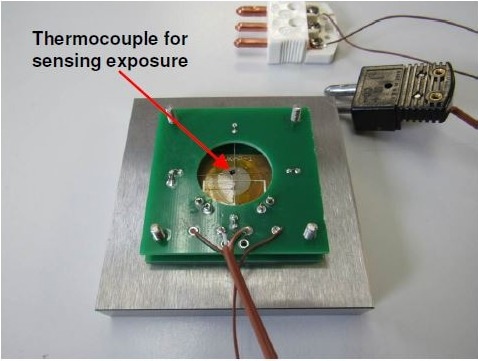

The Quick-Connect Fixture features a cover that securely attaches to a steel base via magnetic clamping. Spring-loaded pins on the cover establish contact with the UV Cure Sensor, facilitating seamless connection to the LTF-631 High Speed Dielectric Cure Monitor. Positioned above the sensor, a suspended thermocouple heats up during UV exposure, enabling measurement of irradiation time, duration, and approximate intensity.

Combining the LTF-631 High Speed Dielectric Cure Monitor with the UV Cure Sensor and the Quick-Connect Fixture forms a comprehensive system for testing UV-cured resins. Integrated with CureView data acquisition and analysis software, the LTF-631 offers real-time measurement of cure state, surpassing any other method for studying these materials in terms of speed.

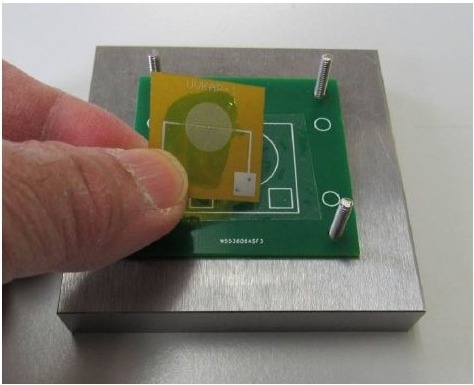

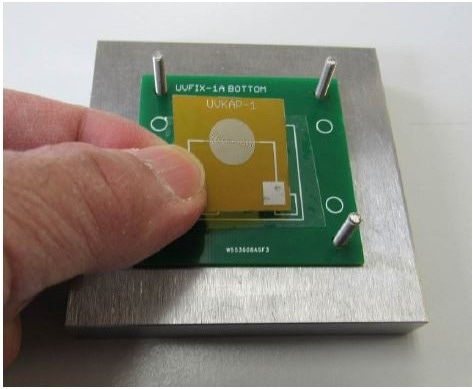

Figure 1. UV Cure Sensor (left) and Quick-Connect Fixture (right). Image Credit: Lambient Technologies

Sensor Specifications

Source: Lambient Technologies

| . |

. |

| Dimensions |

Length x width: 2.54 cm x 2.54 cm (1.00” x 1.00”)

Thickness: 100 um (0.004”)

Width, electrode: 100 um (0.004”)

Spacing, electrode: 100 um (0.004”) |

| Composition |

Substrate: Polyimide

Electrodes: Copper with tin flash |

| Operational Temperature |

Maximum tolerance: 375 °C (700 °F)

Maximum for measurement: 100 °C (212 °F) |

| Sensor Parameters |

A/D ratio = 26 cm

Base capacitance = 20 pF* |

| Temperature sensor |

None |

* Actual value may vary

Quick-Connect Fixture Specifications

Source: Lambient Technologies

| . |

. |

| Dimensions, base |

Length x width: 7.62 cm x 7.62 cm (3.00” x 3.00”)

Thickness: 1.27 cm (0.50”) |

| Weight, base |

0.6 kg (1.3 lb) |

| Composition, base |

Mild steel |

| Composition, cover |

FR4 glass-reinforced epoxy laminate |

| Themocouple |

Type J |

Use of UV Cure Sensor with Quick-Connect Fixture

Figure 2. UV Cure Sensor. Image Credit: Lambient Technologies

Figure 3. Quick-Connect Fixture base. Image Credit: Lambient Technologies

Figure 4. Placing sensor carrier on base. Image Credit: Lambient Technologies

Figure 5. Applying non-adhesive, reusable cling film to sensor carrier. Image Credit: Lambient Technologies

Figure 6. Placing UV Cure Sensor on carrier. Image Credit: Lambient Technologies

Figure 7. Adhesiveless film secures UV Cure Sensor to carrier for easy application and removal. Image Credit: Lambient Technologies

Figure 8. Placing top cover over UV Cure Sensor after application of resin. Image Credit: Lambient Technologies

Figure 9. Assembled Quick-Connect Fixture with UV Cure Sensor. Image Credit: Lambient Technologies

Figure 10. Removing UV Cure Sensor after test. Image Credit: Lambient Technologies

Figure 11. Placing new UV Cure Sensor on reusable cling film for next test. Image Credit: Lambient Technologies

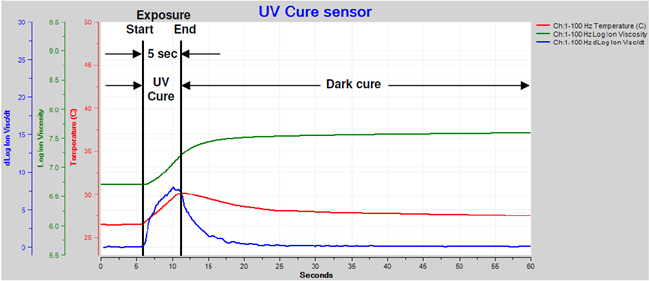

Figure 12. Test of Quad-Cure 1933 with UV Cure Sensor in Quick-Connect Fixture, five-second exposure. Image Credit: Lambient Technologies

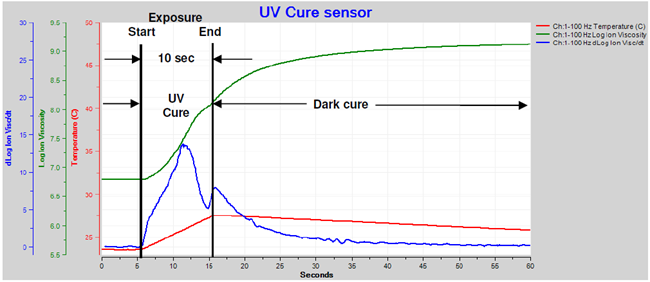

Figure 13. Test of Quad-Cure 1933 with UV Cure Sensor in Quick-Connect Fixture, 10-second exposure. Image Credit: Lambient Technologies.

Figure 12 illustrates ion viscosity, the slope of ion viscosity, and temperature data gathered during a test of Quad-Cure 1933, a UV-curable acrylate adhesive produced by Incure. The resin underwent a five-second exposure to a broad-band UV/visible arc light, as evidenced by the temperature rise between 6 and 11 seconds.

Upon the cessation of irradiation, the temperature declined, demonstrating how the thermocouple integrated into the Quick-Connect Fixture verifies the timing and duration of exposure.

Ion viscosity, indicative of a cure state, steadily rose post-irradiation commencement and persisted even after exposure cessation. The phenomenon of dark cure, attributed to enduring photoinitiator presence, eventually concluded around the 30-second mark, as depicted by the near-constant ion viscosity level at that juncture.

Figure 12 demonstrates a change in ion viscosity of approximately 0.75 units on the logarithmic scale, corresponding to a specific increment in the degree of cure. Figure 13 depicts another trial of Quad-Cure 1933, subjected to identical UV irradiation intensity but extended exposure lasting 10 seconds.

Similar to the initial test, Figure 13 illustrates both UV cure and dark cure processes. However, the dark cure persisted beyond 60 seconds and led to a substantially larger change of 2.45 units in ion viscosity on the logarithmic scale. This change corresponds to an elevated degree of cure resulting from prolonged exposure.