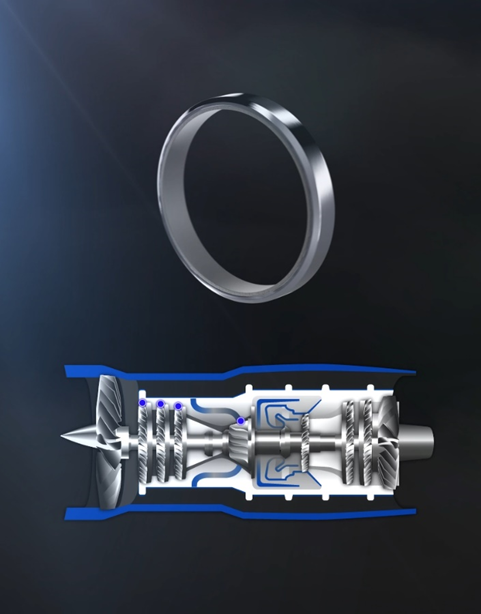

In today's competitive aerospace and turbine industries, efficiency and reliability are paramount. As technology advances, the need for precision-engineered solutions that address complex challenges has never been greater. Technetics, a leader in innovative sealing solutions, introduces its FELTMETAL™ Abradable Seals, designed to meet these demands head-on. These seals offer an alternative approach to reducing turbine blade-to-shroud gaps, maximizing performance and durability even in the most extreme conditions.

Technetics has created a method to handle all challenges head-on. The FELTMETAL™ Abradable Seals decrease the gap between the turbine blade and shroud, ensuring maximum efficiency and dependability.

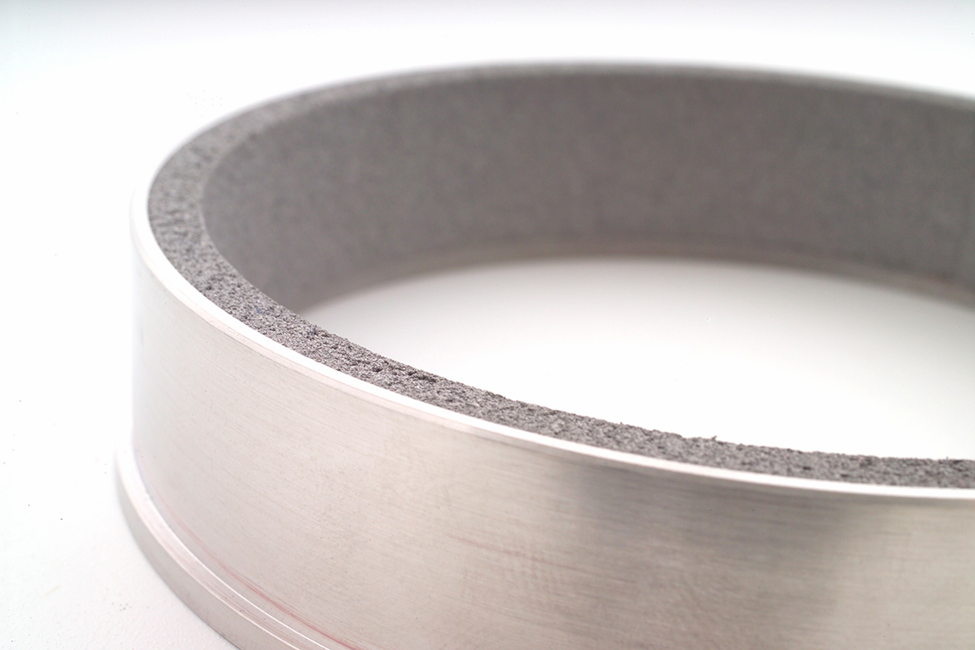

These seals are comprised of a fiberized metal structure sintered to a certain density, usually between 18% and 40% of a solid alloy. As the turbine expands at higher temperatures, the blade cuts through the abradable material, forming a groove unique to the blade and reducing leakage.

The FELTMETAL™ material is designed to reduce blade damage and prevent debris from polluting downstream systems.

Image Credit: Technetics Group

Key Features of FELTMETAL™ Abradable Seals

Tight Clearance Control

The seals are precision-engineered to the ideal thickness, allowing for precise clearance control while maintaining performance.

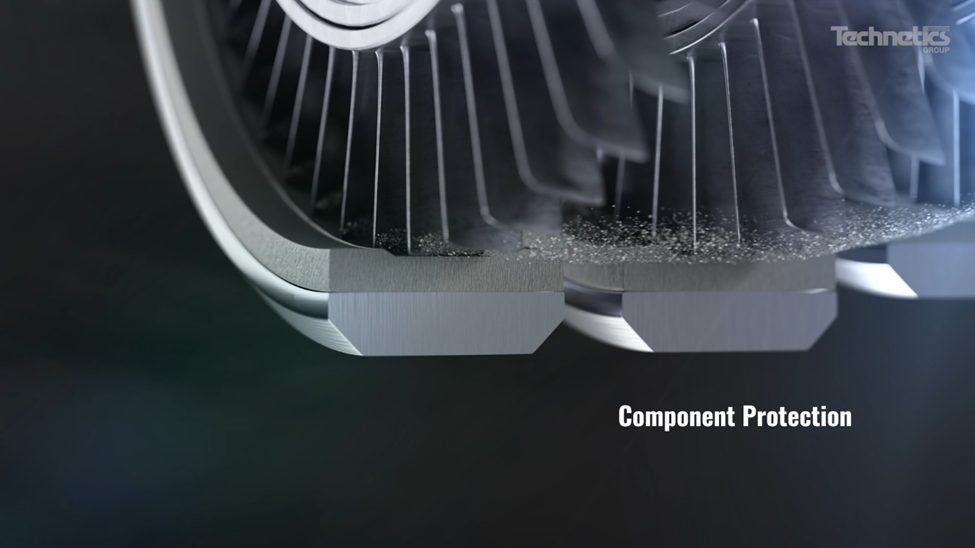

Component Protection

Image Credit: Technetics Group

FELTMETAL™ Abradable Seals protect turbine blades from possible intrusions during machine cycles, extending the life of crucial components.

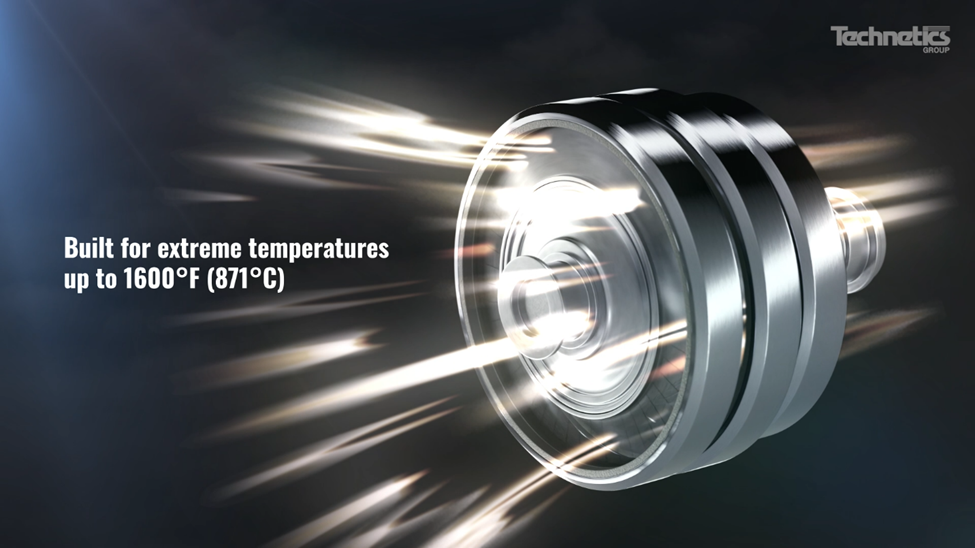

Temperature Resilience

The seals are designed to endure severe temperatures of up to 1600 °F (871 °C), ensuring their integrity and effectiveness in the hardest working circumstances.

Revolutionize Small Turbine Efficiency with Technetics' FELTMETAL Abradable Seals

Revolutionize Small Turbine Efficiency with Technetics' FELTMETAL Abradable Seals. Video Credit: Technetics Group

Heat Dissipation

Image Credit: Technetics Group

The material's porosity enables minimum airflow to disperse heat. The convoluted path "traps" air within the pores prevents a leakage channel.

Customization

Technetics has decades of experience tailoring FELTMETAL™ Abradable Seals to individual system demands, including development choices to solve unique erosion and abradability concerns.

Installation Advantages

The FELTMETAL™ Abradable Seals are intended for easy installation, expediting the procedure.

Pre-Brazed Options

The seals are available in solid or segmented metal housings and are pre-brazed, ready to be press-fitted, or bolted into position. This removes the need for extra brazing or spraying, which saves time and reduces complexity.

Versatile Integration

The seals can be designed to braze into the current housing materials, ensuring a smooth connection with the engine components.

Why Choose FELTMETAL™ Abradable Seals?

Image Credit: Technetics Group

Technetics understands the unique requirements of small, high-performance engines in an industry dominated by huge turbines. The FELTMETAL™ Abradable Seals are an excellent solution for small turbine applications due to their numerous benefits.

Efficiency and Effectiveness

They redefine sealing efficiency and effectiveness by removing the requirement for brazing or spraying in favor of press-fit or bolted solutions.

Proven Reliability

The seals guarantee dependable performance in the most challenging conditions since they are supported by decades of knowledge and a dedication to quality.

FELTMETAL™ Abradable Seals from Technetics address problems that turbine and aerospace engineers encounter. Thanks to the seals’ precise clearance control, component protection, temperature resilience, and customizable choices, compact turbine engines can run at their best.