New research in the journal ACS Sustainable Chemistry Engineering shows a way of constructing a carbon recycling plant (CRP) to create methanol using the developing electrochemical reduction (ER) of carbon dioxide.

Study: Deep Decarbonization of the Cement Sector: A Prospective Environmental Assessment of CO2 Recycling to Methanol. Image Credit: Banana Republic images/Shutterstock.com

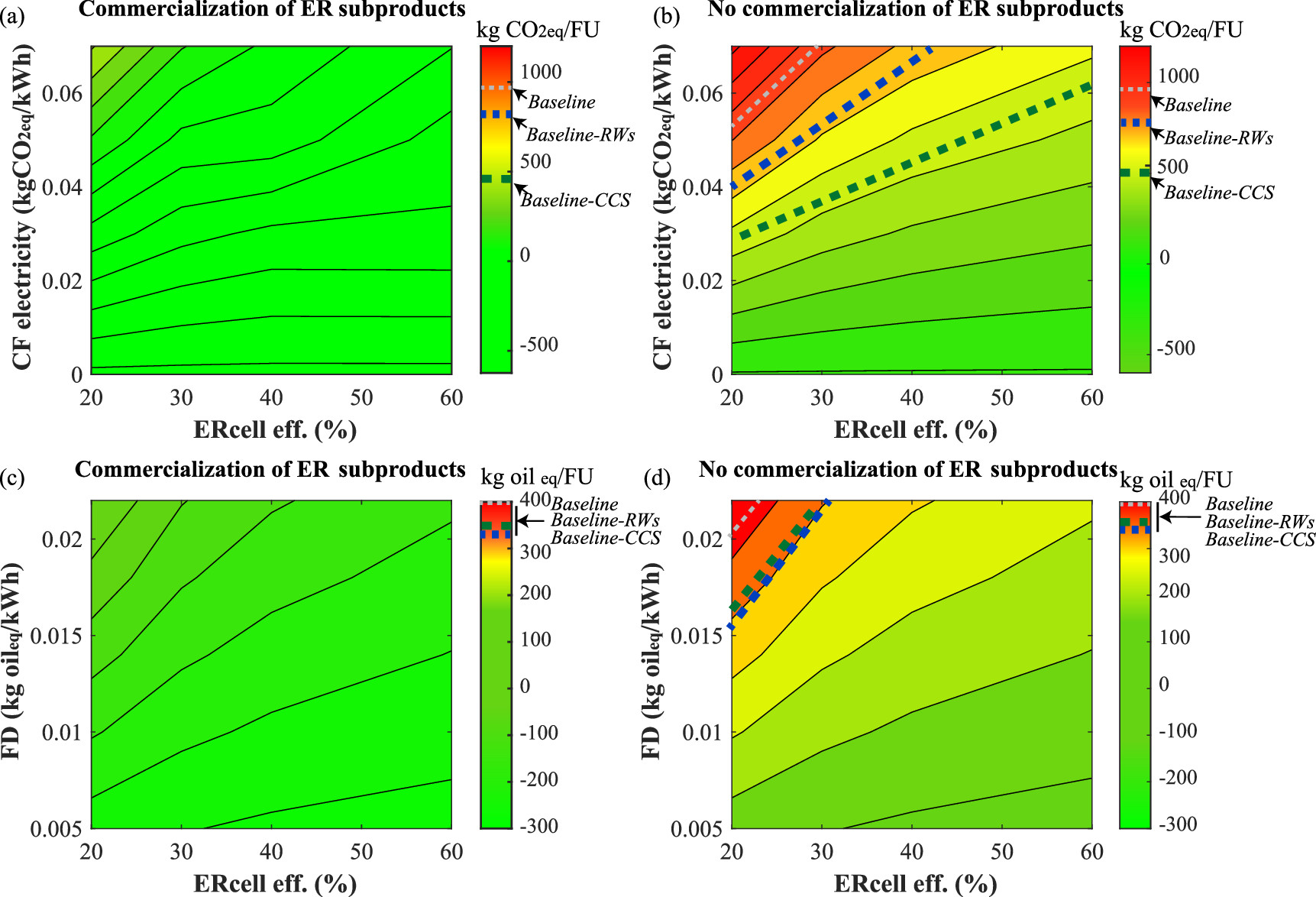

The goal of the research is to show that synergic decarbonization and defossilization may be achieved in the cement and methanol markets, respectively. The essential performance criteria of cell energy efficiency and MeOH concentration have been found as being about 40%-60%, respectively, to guarantee a future sustainable adoption of ER to the methanol technology.

Concrete Industry as Carbon Dioxide Sources

The concrete industry, a probable binding substance around the world, is among the top carbon dioxide (CO2) sources. Within this difficult-to-abate sector, CO2 is primarily published by the reaction steps in clinker production, and although fuel combustion, normally coal, petcoke, and natural gas, accounts for the remaining CO2 direct emissions (30%).

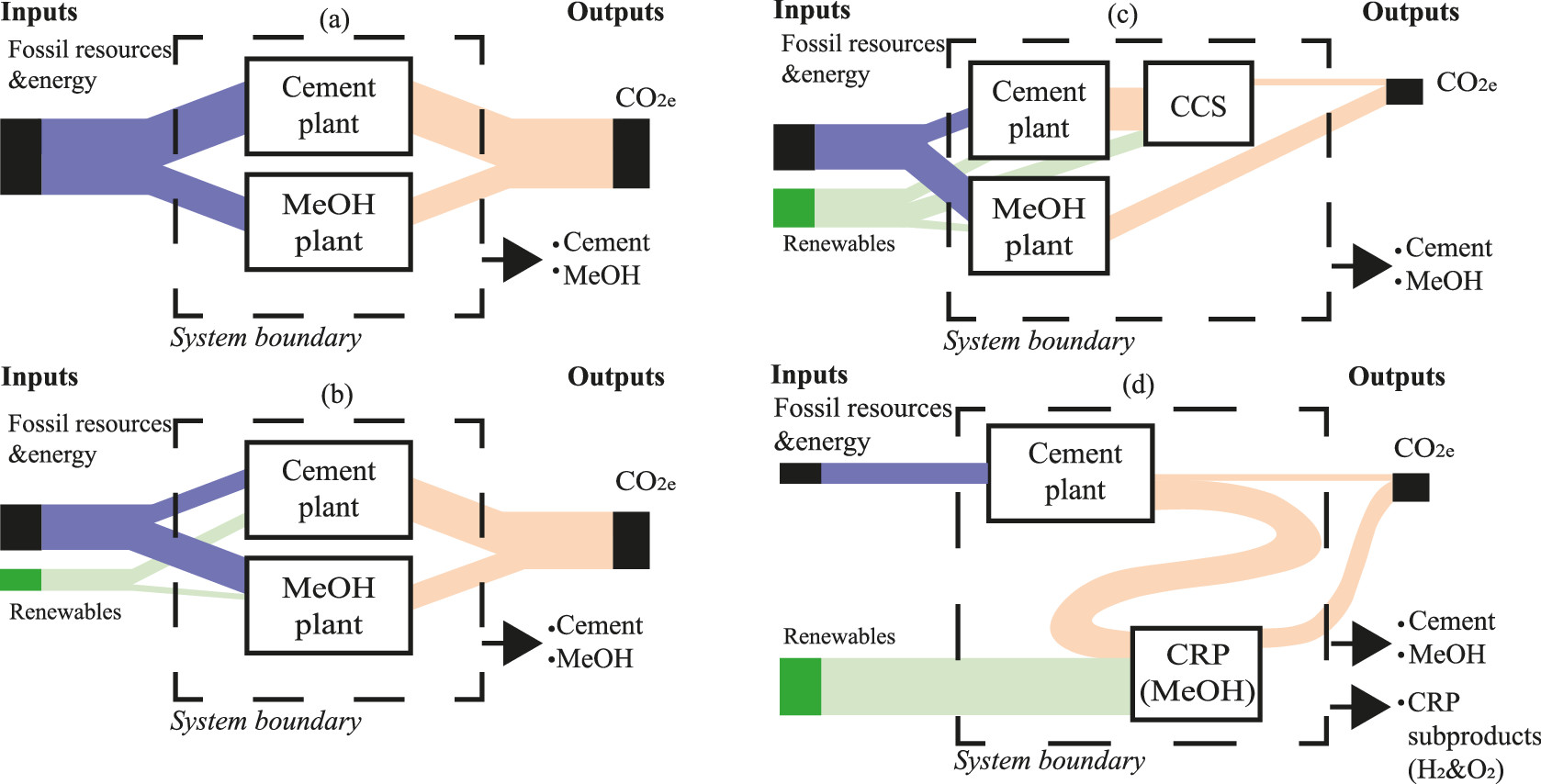

System boundary of scenarios: (a) Baseline (conventional); (b) Baseline-RWs; (c) Baseline-CCS; and (d) S-CRP. mage Credit: Rumayor, M., et al., ACS Sustainable Chemistry

Decarbonization of cement production is currently difficult due to a lack of economic incentives, which limits the available CO2 strategies to mitigate. In the coming years, additional policy efforts will be required. Potential strategies for reducing greenhouse gas emissions in this difficult-to-abate sector have been suggested.

Potential strategies for reducing carbon emissions in this difficult-to-abate sector have been suggested. These include increasing cement process energy savings, switching to lower carbon-based fuels; promoting resource efficiency (lowering the clinker-to-cement ratio), and incorporating carbon capture, utilization, and/or sequestration (CCUS) innovations.

Techniques to Reduce CO2 and Its Challenges

Some techniques, such as improving the energy efficiency, seem to be in place, while others, including those related to the reduced emissions potential of renewable fuels and clinker replacement, are anticipated to be executed in the short to midterm. On the contrary, the industrialization of most evolving CCUS innovations may take over 20 years.

Despite this, CCUS execution in cement production will be required because it can contribute to effectively reducing CO2 emissions from the calcination stage. As a matter of fact, according to the International Energy Agency's (IEA) cement decarbonization blueprint, CCUS could account for approximately 48 percent of CO2 emission reductions by 2050.

Some technical challenges must be overcome in order for massive CO2 reprocessing into value-added various chemicals to be feasible, realistic, and attainable from both a financial and an environmental standpoint.

Sensitivity assessment of the influence of prospective CF and FD of PV solar electricity and the energy efficiency of the ER cell in the impact categories CF (a,b) and FD (c,d) with and without the commercialization of H2 and O2 subproducts. mage Credit: Rumayor, M., et al., ACS Sustainable Chemistry

Potential Decarbonization Circumstances

When a combination of 50% hydrogen (H2) and 50% biomass is being used in the kiln and 83.3 percent biomass with 16.7 percent plasma is being used in the calciner, a potential decarbonization circumstance for cement production with complete removal of CO2 emissions linked to fossil fuel has been used and proven successful.

Researchers suspected that a net-zero-emission concrete kiln could be pictured using a suitable mix of efficiency gains and Carbon capture from process emissions. Meanwhile, both fuel switching and CCUS still necessitate the use of cutting-edge technologies. Today, CO2 capture in the cement industry is nearing commercialization, with China having the world's largest CO2 capture facility.

A New Way to Capture Carbon Dioxide in The Factory

A new capture factory based on ammonia chemical absorption in the Norcem cement factory is expected to demonstrate CO2 capture on a massive scale (Brevik, Norway). It is expected to retain 50% of the factory's emissions using excess heat surpluses. The CO2 acquired will be liquidized and stored beneath the North Sea.

Despite the fact that many Carbon capture technologies are on the verge of commercialization, the environmental and economic viability of innovations for using captured CO2 remains unknown. The majority of them seem to be in their infant stages, with nutrient carbonatation to additives and CO2 hydrogenation to methanol on a commercial level.

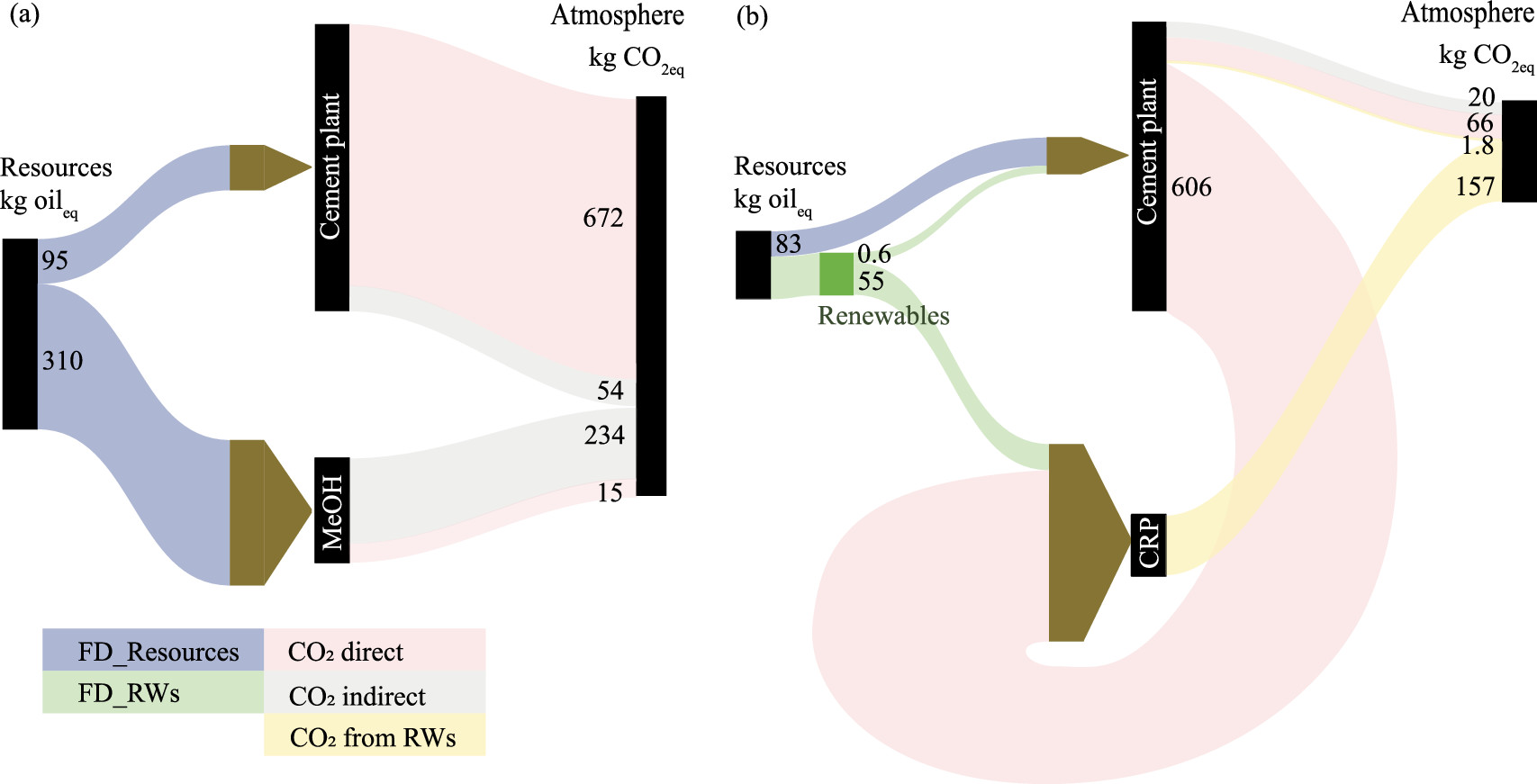

FD and carbon emissions for the production of cement (1 ton) and MeOH (429 kg) in (a) Baseline and (b) long-term low-carbon S-CRP (cradle-to-gate approach). Image Credit: Rumayor, M., et al., ACS Sustainable Chemistry

Capturing Carbon Dioxide and Turn it to Methanol

To date, the most fully developed near-carbon-neutral innovation for long-term carbon reduction of cement factories is burying CO2 underground via CCS. The cost and energy charge are its primary challenges, preceded by the location and potential of storage sites.

Several attempts have been undertaken to increase the stability of Carbon dioxide with ER performance, including improving the catalyst design to minimize deactivation, improving electrode and membrane engineering, and making system-level changes.

The research concentrated on the electrochemical reduction (ER) production of methanol, a critical building block, and fuel, which is discovered at low technical readiness levels in order to accelerate its further development.

In combination with other prospective solutions such as CCS, the future sustainable application of this conversion technology in hard-to-abate industries like cement can assist in closing the anthropogenic carbon cycle, offering defossilization of the conventional methanol market.

Future Research

Presently, efforts are concentrated on scaling up such a CO2 recycling process as soon as possible in order to make the decarbonization endeavor worthwhile in this difficult-to-address sector.

References

Rumayor, M., et al. (2021). Deep Decarbonization of the Cement Sector: A Prospective Environmental Assessment of CO2 Recycling to Methanol. ACS Sustainable Chem. Eng. Publication Date:December 11, 2021 https://pubs.acs.org/doi/10.1021/acssuschemeng.1c06118

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.