In recent years, biomass produced from organic waste materials has become the focus of research for sustainable alternatives to hydrocarbons for biofuel and solvent production. However, there are issues with contamination from numerous elements, which must be removed to optimize the synthesis of these valuable biomaterials.

Study: Ultrasound-Assisted Demineralization Process of Sugarcane Straw and Its Influence on the Further Biomass Conversion. Image Credit: Yatra/Shutterstock.com

A paper published in Sustainability has explored the use of ultrasound energy during the demineralization process to provide improvements to their use.

Lignocellulosic Biomass: A More Sustainable Alternative to Fossil Fuels

The urgent need to achieve net-zero carbon emissions by 2050 has crystallized the search for alternative fuel and energy sources. Biomass has been explored extensively for this purpose. However, using food products as biomass presents issues with food security, with arable land that could otherwise be used for food growth and livestock rearing given over to crops destined for industrial purposes.

Second-generation feedstocks have emerged as a more viable alternative. These organic materials are a byproduct of sectors such as the food and agricultural industries that would otherwise be wasted, meaning that their potential as a viable industrial material is lost. Additionally, lignocellulosic materials trap carbon dioxide, helping to achieve net-zero carbon emissions. They are a carbon-neutral material, which has huge advantages over traditional hydrocarbons.

A second-generation feedstock material that has garnered attention is sugarcane straw. This material is mainly composed of cellulose (~45% wt.) hemicellulose (~28% wt.) and lignin (~18% wt.) This feedstock is incredibly versatile, making it suitable for a variety of industrial activities.

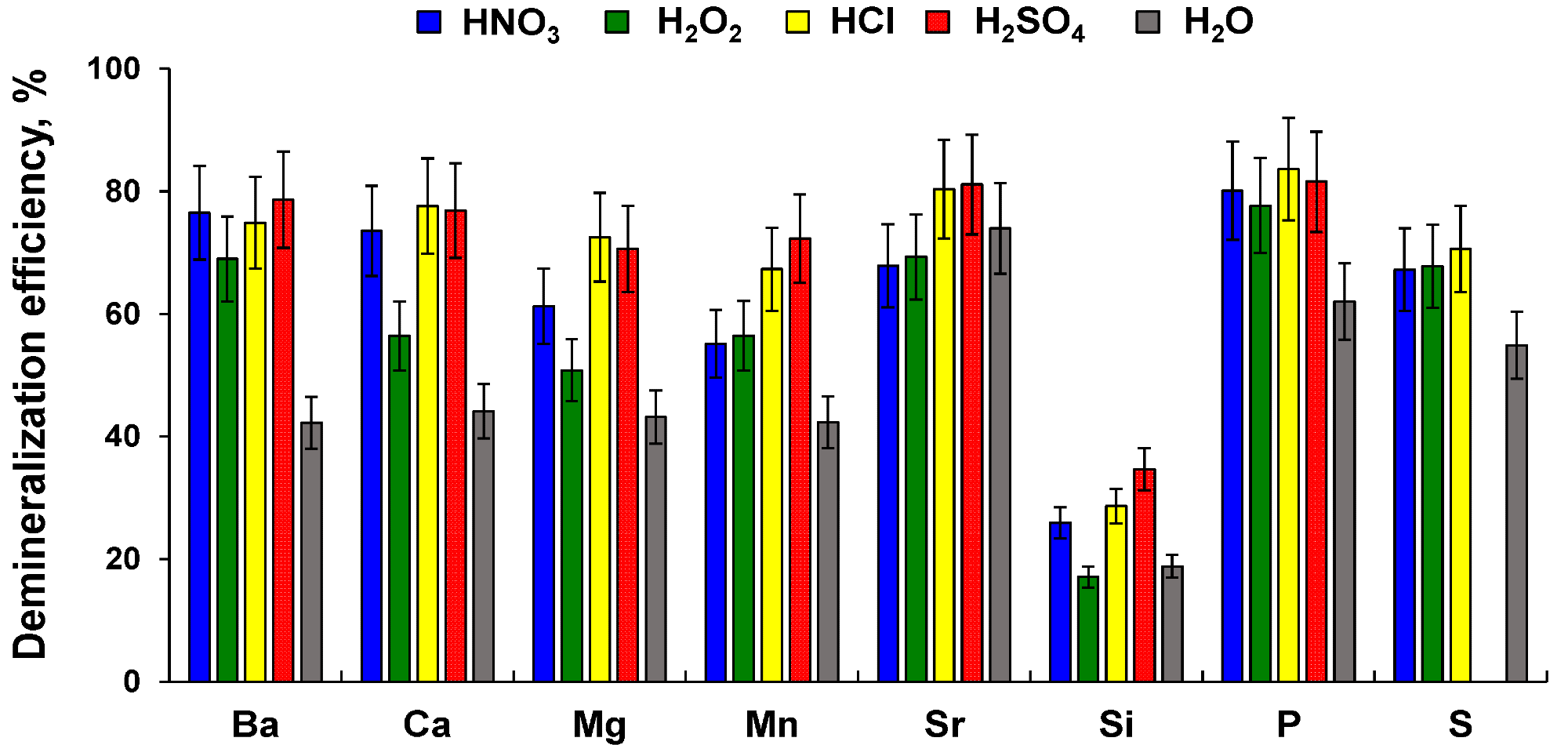

Demineralization efficiency with several extraction solutions using an ultrasonic bath operating at 25 kHz (100 W). Experimental conditions: 250 mg of sugarcane straw, 20 mL of 15% (v v−1) extraction solution for 30 min at 70 °C, and 70% of US amplitude (error bars are the standard deviation, n = 3). Image Credit: Santos, D et al., Sustainability

The Issue with Mineral Contamination

However, despite its potential as a green feedstock alternative to produce sustainable alternative fuels and chemicals, there is a drawback to using lignocellulosic biomass: contamination with metallic and nonmetallic minerals, soil, and ash. This causes problems with corrosion and incrustation in pipelines and refineries, as well as problems with reduced calorific energy availability. For these reasons, until recently sincere consideration was not given to these waste materials as industrial feedstocks.

Lignocellulosic biomass needs to be pretreated before use if it is to be valorized. The lignocellulosic material must be fragmented, and lignin, cellulose, hemicellulose, and inorganic materials separated. One step which must be implemented in the process is demineralization, where inorganic contaminants are removed from the material’s matrix to improve it.

Conventional Demineralization Processes

Conventional demineralization processes typically require the use of diluted solutions of acids. The issues with these processes have facilitated the search for alternatives. Conventional approaches require lengthy extraction periods and must be performed at a relatively elevated temperature. Whilst they remove the contaminants, these pretreatment processes have the negative effect of significantly degrading the biomass.

Recent studies have demonstrated alternative demineralization approaches including the use of supercritical fluids, Soxhlet extraction, and high-speed mechanical stirring. Whilst these improve the efficiency of demineralization, they reduce industrial viability.

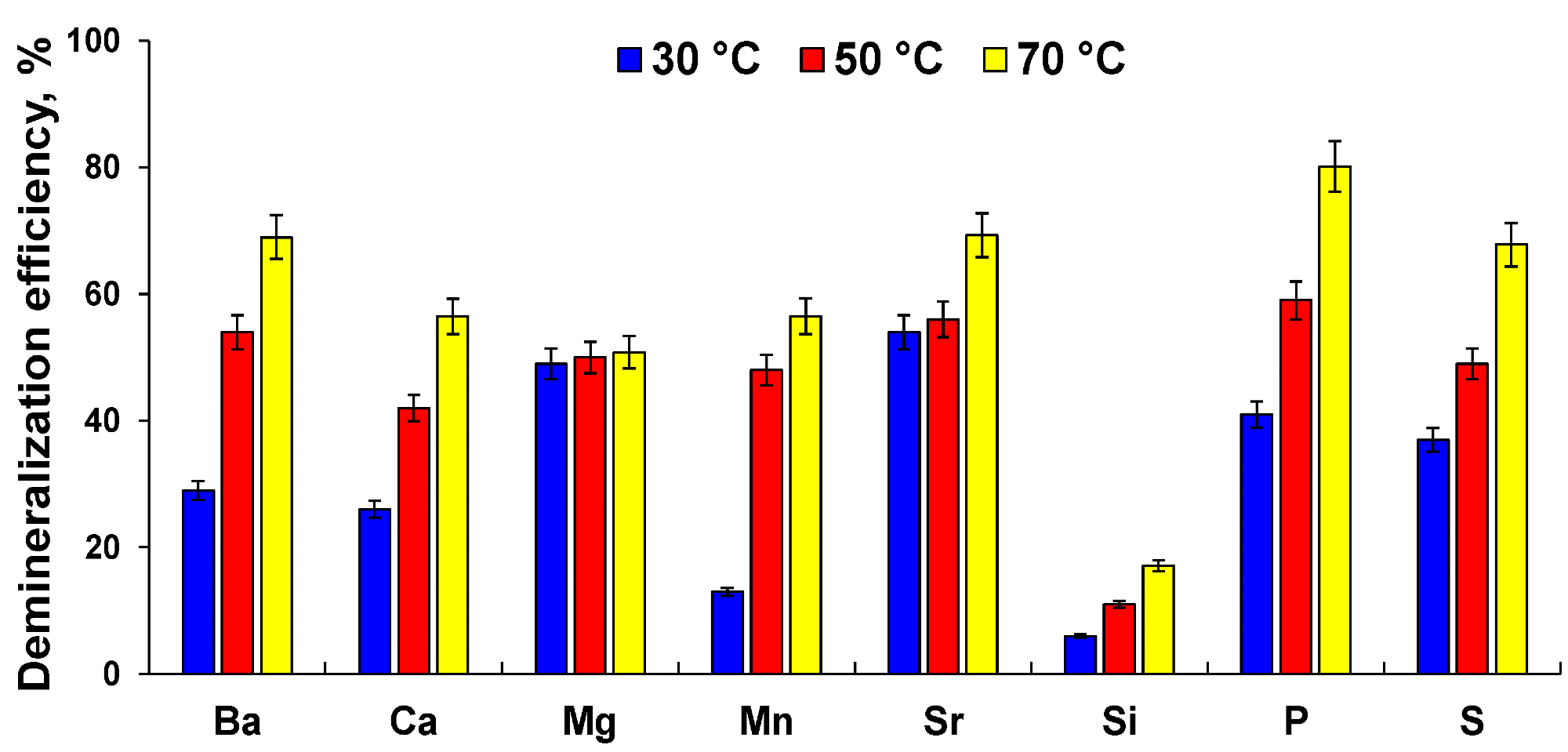

Demineralization efficiency with several extraction temperatures using an ultrasonic bath operating at 25 kHz. Experimental conditions: 250 mg of sugarcane straw and 20 mL of extraction solution 15% (v v−1) for 30 min and 70% of US amplitude (error bars are the standard deviation, n = 3). Image Credit: Santos, D et al., Sustainability

Using Ultrasonic Energy for Demineralization

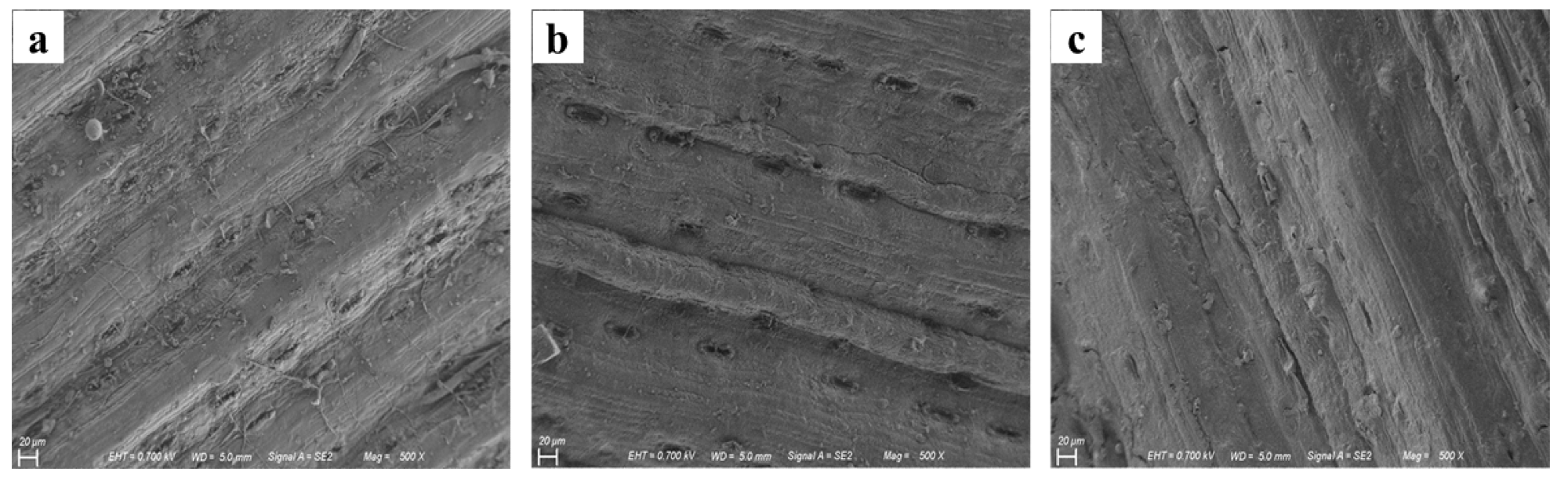

An attractive alternative to these processes that overcomes their limitations is the use of ultrasonic (US) energy. Mass transfer of the biomass to the solvent is improved with this method. Alternative cycles of expansion and contraction facilitate the propagation of US waves.

The cohesive forces of liquids can be overcome during the rarefaction cycle, forming microbubbles of gas within the liquid which then reach a critical size and collapse. This cycle of microbubble formation, rebirth, and collapse is known as acoustic cavitation. This causes a release of energy due to shockwave formation, erosion, microjets, and radical formation. The energy released by the process promotes the demineralization of biomass.

SEM images of: (a) untreated sugarcane straw; (b) sugarcane straw after treatment with US; and (c) sugarcane straw after treatment with mechanical stirring. Image Credit: Santos, D et al., Sustainability

The Study

The authors of the study published in Sustainability have demonstrated the use of US energy to promote the demineralization of lignocellulosic biomass. Sugarcane straw was selected for the biomass, and US energy was used to extract Ca, Mg, P, S, Si, Mn, Sr, and Ba elements from it. The UAD (Ultrasound-assisted demineralization) process was assessed with these elements.

The parameters evaluated were the frequency and delivered power of the US bath systems used and the demineralized solution. UAD process efficiency was compared to mechanical stirring. Additionally, process scaling experiments using an ultrasonic reactor were performed.

Results of the study demonstrated that ultrasound treatment achieved enhanced extraction efficiency compared to mechanical stirring. The authors stated that this was due to physical and chemical effects which were produced by ultrasound treatment. Moreover, the yield of fermentable sugars was improved by 55%. The authors concluded that ultrasound-assisted demineralization can be considered as a viable alternative process for the removal of minerals from lignocellulosic biomass.

Further Reading

Santos, D et al. (2022) Ultrasound-Assisted Demineralization Process of Sugarcane Straw and Its Influence on the Further Biomass Conversion [online] Sustainability 14(1) | mdpi.com. Available at: https://www.mdpi.com/2071-1050/14/1/557

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.