Nov 15 2007

When large rubber-insulated cables for a lift bridge connecting Minnesota and Wisconsin failed after less than two years in service, Northwire Inc. had a ready solution: replacement cable insulated with DuPont™ Hytrel® thermoplastic elastomer.

Because Hytrel® provides effective electrical insulation and toughness in thin layers, the replacement cables using Hytrel® are more than 40 percent smaller in diameter than the one that failed. “Smaller cable diameter means longer flex life at a given bend radius,” said Ted Beach, director of sales for Northwire.

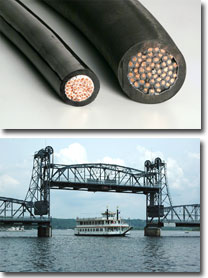

Slimmer profile of cable insulated with DuPont™ Hytrel® (top) indicates longer flex life than rubber-insulated cable (bottom) that failed after less than two years of service on lift bridge.

Slimmer profile of cable insulated with DuPont™ Hytrel® (top) indicates longer flex life than rubber-insulated cable (bottom) that failed after less than two years of service on lift bridge.

Hytrel® is ideal for cables that flex because its combination of high dielectric strength and toughness allows its use in thinner layers than many alternative materials. Another advantage for Hytrel® is productivity and stability during extrusion of such thin insulation layers.

Northwire also is bringing the benefits of Hytrel® for insulation to manufacturers and end-users of robots, other industrial automation equipment and retractable coiled cable for various applications.