Nov 13 2008

Madrid Institute of Advanced Studies in Materials, IMDEA Materials, to form part of strategic national consortium awarded CENIT programme to research new magnesium-based transport technologies.

The MAGNO programme is a national consortium with a total budget of €30 million over 4 years, made up of 12 companies (4 corporations and 8 SMEs) and 11 technology centres. It has been set up to promote and develop new technologies based on magnesium alloys. This CENIT, a Spanish acronym standing for Strategic National Consortium for Technical Research, is led by the Antolín Group, a leading multinational in the design and production of car interior components and modules. The high-tech investment programme will give a boost to the metal industry in Spain, as well as making the country one of the leaders in an expanding market of the future.

IMDEA Materials will contribute to the consortium by carrying out research aiming to improve the mechanical behavior at high temperature and high strain rate (shock conditions) of currently used cast and forged Mg alloys, by optimising casting processes and by developing novel Mg alloys with enhanced mechanical performance.

At a time of record-breaking oil prices, light transport is no longer a luxury but a necessity. The fuel saving would not only ease the strain on people's wallets, it would also significantly reduce gas emissions, with the resulting benefit for the environment.

Magnesium is one of the lightest metals. Its low density, 1.7 g/cm3, makes it a key material in reducing the weight of cars and it could replace certain parts made of steel (7.8 g/cm3) or aluminium (2.7 g/cm3). Moreover, it is found in abundance in the Earth's crust and is easy to recycle and machine. Its specific mechanical resistance is excellent, even exceeding that of steel.

Magnesium was first isolated in 1808 by Sir Humphrey Davy. Due to its high inflammability in powder form, until the end of the 19th century it was used exclusively to produce artificial light or as a photographic flash. However, its use soon extended to the transport industry and by 1939 the Volkswagen Beetle included 20 kg of magnesium. Today, China is the largest producer of magnesium in the world and production costs have reduced dramatically, now being comparable to aluminium.

However, large-scale commercial use of magnesium in consumer vehicles is still some way off, as its mechanical resistance to high temperatures and corrosion has still not been improved sufficiently. For this reason, magnesium cannot be used to manufacture parts located on the vehicle exterior or in areas close to the engine. Furthermore, at present most parts are made through casting because, due to its hexagonal structure, magnesium is difficult to shape.

This project falls within the strategic lines of applied research that the IMDEA Materials Foundation has defined in its scientific programme.

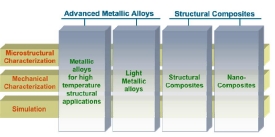

As the diagram shows, one of IMDEA Materials' main lines of research is Advanced Metallic Alloys and in particular alloys based on light metals such as magnesium. This line has a team of world-class researchers, who will be working on this ambitious project over the next four years