Imatek has recently installed its Integrated High Speed Video system at the Corus Swinden Technology Centre (STC) in Rotherham.

The new system will be used to improve understanding of the performance of steel at high rates of strain and for other general applications.

Corus is Europe's second largest steel producer with annual revenues of around £12 billion and a crude steel production of over 20 million tonnes.

Since April 2007 Corus has been part of the Tata Steel Group, the world's sixth largest steel producer. Corus is a leading global supplier to many of the most demanding metal customers around the world.

The Research, Development and Technology business of Corus employs almost 950 researchers across Britain and the Netherlands.

Corus works in collaboration with universities and research institutes all over the world as well as with key customers in the automotive, transport, packaging and construction areas.

The Swinden Technology Centre in Rotherham, South Yorkshire, is the main R&D site in the UK focusing on product research and applications research for the transport and building & construction sectors.

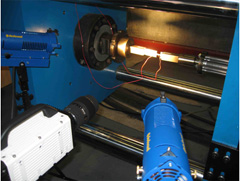

Imatek’s Integrated High Speed Video system uses its C3008 data acquisition system to combine signals recorded during a test event together with high speed video imagery, all under the control of Imateks ImpAcqt software. Since the camera and the data acquisition share the same trigger, data points and images can be precisely correlated. A video sequence provides a great deal of qualitative information about the test event, and the software also allows quantitative information to be extracted.

Integrated High speed video offers an advantage in many application areas and is available as an option for any of the Imatek range of impact testers or in a stand-alone mode, making it a general purpose tool that can be utilised by other parts of a customers operation and on a wide range of test apparatus including UTM’s, pendulum and drop weight testers.

As standard the High Speed Video option provides a complete package including C3008 data acquisition, software, camera, choice of lenses, lighting controller, lights and tripods/stands.

Imatek is a leading UK based manufacturer of materials testing equipment primarily in the fields of impact testing and polymer melt rheology. Imatek’s products are used all over the world to test the properties of materials, components and assemblies in industries such as aerospace, polymer processing, steel production, automotive and academic research.