Apr 17 2009

The Technology Partnership (TTP) has launched a portfolio of new droplet generation and control technologies targeted at 'smart' materials industries.

Applications include the production of high quality engineered powders and emulsions, and multi-layered and encapsulated particle generation. In each offering TTP is addressing the industry's requirement for improved performance and process flexibility.

TTP has leveraged its experience in digital printing and electronic aerosols to develop a number of proprietary droplet and spray generation solutions offering significant technical advantages over traditional industrial spray technologies. These patented technologies offer precise droplet size, velocity, and positional control. Significantly, they also enable the delivery of formulations which are difficult or impossible to atomise using traditional technologies such as higher viscosity or particle-loaded fluids.

TTP has worked with a number of partners to develop its droplet technologies for a diverse range of industrial processing applications. James McCrone, TTP, explains: "Typical current processes are poorly controllable, often requiring additional post-processing steps. We help our clients to push the boundaries of droplet and particle formation and control, enabling new industrial processes and improving the performance of existing processes."

TTP brings a strong toolbox of droplet engineering capabilities:

- Size control from sub-micron to tens of microns

- Flexible process conditions - from high solvent content to viscous liquids, across a wide temperature range

- Droplet collision and reaction

- Generation of highly engineered emulsions

These technologies provide a comprehensive toolbox that can be applied to diverse problems even as unusual as precision cleaning. For example the precise control of droplet momentum enabled by TTP's technology was critical to a non-damaging cleaning process. Elsewhere TTP's spray technology is producing ultra-fine, sub-micron powders by spray drying. Finally, a current development within the printing industry is taking advantage of TTP's ability to generate particles of a highly aggressive, particle-laden solvent formulation.

The printing and spray-coating of complex reagents is another field in which TTP's technologies are delivering results for its clients. TTP's droplet technology has the potential to deliver a new level of precision in both the production of biological test strips and arrays. More routinely TTP applies its technology to applications such as web coating and other coating applications. Here precise flow-rate and droplet size control can enable complex fluids to be deposited more evenly and efficiently than existing technologies.

Supporting images:

http://www.eml.com/images/ttp018.jpg - A high-quality powder created using TTP's spray technology. The average particle size is below one micron, with a narrow size-range distribution.

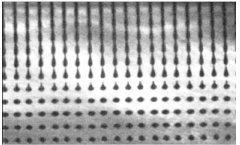

http://www.eml.com/images/ttp019.jpg - An array of droplets being created using CSpray technology, demonstrating the exceptional control possible over droplet breakup. This technology is suitable for spraying fluids with high solid content, and has applications in the deposition of precisely controlled coatings.