Today Dow Corning Corporation's Electronics group introduced its newest silicone encapsulant, Dow Corning OE-6636, designed for overmolding (compression molding) and dispensing processes.

The product provides for a high refractive index (RI) of 1.54 which enables better light output (see Appendix 1, below), has a low moisture uptake, improves thermal aging and light resistance, and possesses better adhesion to typical substrate for LED packages such as Poly Phthal Amid. Overmolding, a new trend in LED packaging, enables higher throughput than a typical dispensing process, making hundreds of LED packages at a time.

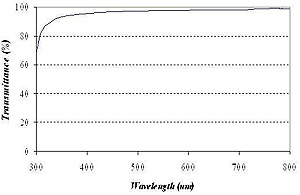

Dow Corning silicone solutions for LED packages are designed to offer good compatibility with standard LED substrates and processing techniques. Its products provide both High RI and Normal RI OE Series silicone encapsulants, which have outstanding light transmittance across the application wavelengths of LEDs. The encapsulants provide excellent stress relief, moisture protection and UV resistance for LED chip sealing protection.

"Dow Corning is a leading innovator in the global LED marketplace. We have been delivering high performance solutions with our expertise in silicon science to meet the unique demands of LED packaging and assembly. We are pleased to introduce OE-6636, a new addition to Dow Corning's substantial OE product line, to help customers continually innovate the LED packaging process," said Kazunori Maruyama, Global Market Manager, Dow Corning Electronics.