Aug 19 2009

Traditional "analog" thermostat temperature-control systems for vehicles will soon be a technology of the past if inventor Tom Hollis has his way. Switching to digital can manage critical fluid systems in a way that significantly improves fuel economy, reduces emissions and engine driveline wear to help extend the life of fluids critical in the operation of engine components.

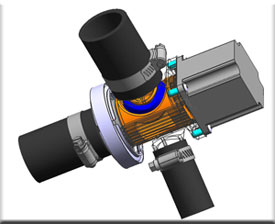

DuPont™ Zytel® HTN PPA resins enhance performance of this digital control valve.

DuPont™ Zytel® HTN PPA resins enhance performance of this digital control valve.

"When you think of the sophisticated systems in a vehicle today, it comes as a surprise that we still use analog systems to control the interaction of the engine with the radiator system," said Hollis, director of Advanced Research -- MileageMatrix, Inc. "After all, those fluids protect the vehicle's most important operating systems - the engine and driveline - and running them too high or too low simply wastes energy."

The Digital Rotary Control Valve (DRCV) will provide a "true" powertrain thermal management system that, after mapping, will always allow the engine/transmission to function at their "known" optimum operating temperatures, under all driving conditions. The computer-regulated system monitors temperatures at several under-hood locations and controls the single DRCV to maintain optimum engine and transmission temperatures, throughout all engine load conditions and extreme ambient temperature ranges.

Developed by Hollis and manufactured by the Minco Group, which includes All Service Plastic Molding, for MileageMatrix Inc., the component relies on DuPont Zytel HTN PPA resins for the valve body, tube and diverter. The materials' resistance to continuous exposure to hot long-life coolant up to 130 degrees celcius, and their retention of properties with moisture proved optimal for this application.

"We had to be sensitive to expansion and contraction because all surfaces are always 'wet' and we needed a 'fluid bearing' to prevent sticking," said Hollis. "Zytel HTN PPA performed well in these conditions, allowing us to take advantage of the lightweight nature of plastics and overall cost advantage over metals."

"The drive for better fuel economy and reduced CO2 is inviting companies to rethink the design of many components," said Steven Mok, DuPont automotive thermal management global segment leader. "This drive opens up our capability to collaborate and help with materials and development support to bring new ideas to market faster than ever."