Imatek have recently completed the successful installation of an IM10R Impact Test System at the Nagoya site of Tokai Rubber Industries in Japan.The system will be primarily used for understanding and developing the impact and energy absorption characteristics of materials used on vehicles for pedestrian safety applications.

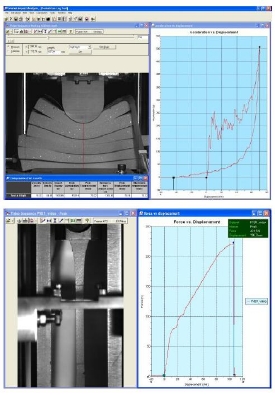

The system has two modes of operation, high-rate tensile tests on standard polymer specimens and dynamic compression testing of polymeric foams and structures containing the same.

In tensile mode the system can test tensile specimens at strain rates in excess of 1000s-1 and yield strengths up to 35KN.

In dynamic compression mode the system uses a light-weight alloy carriage that is fitted with a variety of profiled strikers including child, teen and adult leg-form and head-form strikers, in order to measure energy absorption characteristics of materials and structures at representative speeds of up to 50kph and acceleration of up to 500g.

Tokai is a global company with headquarters in Japan and a strong business network comprising 19 locations in 8 countries. The group employs over 12,000 people and has annual sales in excess of 274 million yen.

During its history, which spans some three quarters of a century, Tokai has become a market leader in the manufacture and sales of automobile components including anti-vibration rubber and hoses. Tokai are a principle supplier to Toyota cars. The company also manufactures rubber components for the IT industry.

Imatek’s IM10 range is extremely versatile and is able to accommodate a wide range of automotive test applications making it an extremely cost effective choice for customers within the automotive sector.

Typical automotive test applications include:

- Standard QC tests on polymers to meet mandatory test requirements. For example, to ensure against brittle failure of key parts such as those that could compromise supplementary safety systems or cause injury to occupants.

- Ensuring against embrittlement of polymers due to paint coatings.

- Testing of alternative materials for suitability, weight reduction and better performance at lower cost.

- Characterising the energy absorption efficiency of polymeric foams, alloys and crush tubes for safety applications such as bumper structures and head, leg and knee protection applications.

- Resilience tests and dynamic fatigue tests of rubbers, such as those used in suspension and steering components.

- Crush testing of structures to assess crash performance, for example structures that are adjacent to or surrounding fuel lines to check susceptibility to damage and therefore crash failure.

- High rate tensile testing of polymers and sheet steels at speeds representative of in-use conditions.

- Impact performance of key structures such as suspension and steering assemblies, alloy and steel castings.

Imatek is a leading UK based manufacturer of materials testing equipment primarily in the fields of impact testing and polymer melt rheology. Imatek’s products are used all over the world to test the properties of materials, components and assemblies in industries such as aerospace, polymer processing, steel production, automotive and academic research.