With the new Simetal EAF Micro, Siemens VAI Metals Technologies has extended its range of steel making solutions to include an electric arc furnace for low tapping weights between 5 and 35 tons. This system has been specifically developed for foundries and micro steel works. It combines the advantages of the electric steel making process with a high degree of flexibility in terms of production volumes and the qualities of the steels produced.

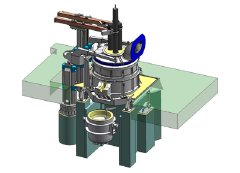

Low tapping weights between five and 35 tons for applications in a foundry or micro steel works: Computer-animated presentation of the Simetal EAF Micro.

Low tapping weights between five and 35 tons for applications in a foundry or micro steel works: Computer-animated presentation of the Simetal EAF Micro.

Nowadays, especially the operators of foundries and micro steel works are having to face the challenge of casting relatively small quantities of steels of different qualities in quick succession. The new Siemens electric arc furnace handles tapping weights from 5 to 35 tons, and combines a high degree of flexibility in the production volume with the advantages of electric steel making with respect to melting and refining. In contrast to conventional melting processes, the integrated oxygen system enables even complex metallurgical process steps - such as deoxidation and decarburization - to be carried out. The electric steel process is also less dependent on the state and heterogeneity of the input materials, thus allowing the use of the widest range of raw materials and qualities of scrap.

The new electric arc furnace has a tilting frame with enhanced dynamic characteristics, and can be installed on a base frame. This design permits a high degree of pre-assembly in the manufacturing phase, and minimizes the time required for installation in the melt shop. The Simetal EAF Micro is based on a modular design. Slight modifications to a few components quickly adapt it to handle the complete range of possible tapping weights.