Morgan Advanced Materials' Wesgo/Duramic business (MTC-Wesgo/Duramic) offers custom made Alumina Fixtures used to isolate and insulate metal components during high temperature brazing processes. MTC-Wesgo/Duramic fixtures have proven to be excellent options when brazing medical and laser industry components, high electrical field devices and magnetic resonance imaging (MRI) equipment.

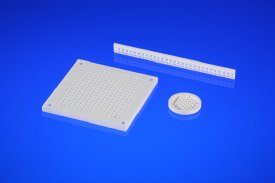

Design and configuration of MTC-Wesgo/Duramic Alumina Fixtures are highly flexible. Both simple and intricate features, including small diameter holes, can be machined to tight tolerances to meet customer requirements. Cleanliness is ensured through a specially designed air firing process. Also, during the brazing process, thermal expansion of the fixture is matched to that of the Alumina insulator used for ceramic-to-metal seals.

MTC-Wesgo/Duramic Alumina Fixtures hold distinct cost and cleanliness advantages over other materials used during the brazing process. Alumina is an economical alternative to molybdenum or tungsten. MTC-Wesgo/Duramic Alumina has an excellent dimensional stability at higher temperatures (greater than 800°C) and a long service life, lasting years rather than months. Also, braze material does not stick to Alumina as it does to other non-ceramic materials.

In addition, Alumina offers a clean solution compared to graphite, which can contaminate surrounding surfaces. Unlike graphite, which converts to carbon monoxide/carbon dioxide over time, MTC- Wesgo/Duramic Alumina shows no material degradation in a wet reducing atmosphere. If the MTC-Wesgo/Duramic Alumina is contaminated with foreign materials, it is easier to see because of its inherent white color. Finally, there is no outgassing or material transfer to parts it is in contact with during vacuum brazing applications.