US company Alton Steel Inc. has become the world's first steel producer to use Siroll Orbis+ to measure the profile of long products. The Siroll Orbis+ fully rotating, on-line gauge for wire rod and bar mills delivers improvements in both product quality and output, while reducing waste. Unlike traditional methods that merely sample a single side, Siroll Orbis+ reviews the entire bar during the rolling process. This enables Siroll Orbis+ to uncover defects when they can be remedied instead of after the product is completed. Orbis, the previous model, has been used by Alton Steel since 1996.

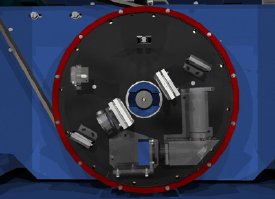

Siroll Orbis+: Optical unit with LED light source and camera.

Siroll Orbis+: Optical unit with LED light source and camera.

Siroll Orbis+ is the latest version of the Orbis system which is currently in use in more than 200 applications worldwide. Like its predecessor, the new Orbis+ measuring system works on the shadow principle and measures the dimensions and profiles of rod steel and rebar of different shapes, including round, flat, square, octagonal and hexagonal cross-sections. The new system can perform more profile measurements per unit of length than other systems available on the market and offers a high degree of precision.

Located in the US federal state of Illinois, Alton Steel Inc. has an annual production capacity of 700,000 metric tons of steel. It produces carbon steel and alloyed steel with the help of an arc furnace and downstream metallurgical equipment. The steel is then formed into billets and slabs of different sizes on a continuous caster. Part of the company's output is sold as semi-finished material. In addition, Alton Steel Inc. has a long-product rolling line for producing Special Bar Quality (SBQ) steel bars with cross-sections between 7/8" (2.2 cm) and 3.5" (8.9 cm).