The combustion of fossil fuels for energy has steadily increased the concentration of greenhouse gases in the earth's atmosphere. Of the numerous trace gases, carbon dioxide is a major component making up the majority of these emissions. Carbon dioxide sequestration involves the capture and secure storage of not only existing amounts of CO2 in the atmosphere, but emitted CO2 as well. Since the Kyoto Protocol, concerns over combustion gas emissions have received a great deal of attention.

There are numerous energy-related approaches to managing CO2 that include several carbon free energy sources (e.g. nuclear, solar, wind, geothermal, and biomass energy). Scientists are also searching for ways to increase the efficiency of energy conversion so that smaller amounts of fossil fuel energy are required for the same energy output. However, although promising, these alternatives currently have a relatively small effect on current fossil fuel demand and usage. Fossil fuels continue to supply the overwhelming majority of the world's energy consumption. Increasing energy demands, the lag in converting to alternative energy sources, the global economic dependence on fossil fuels, and its relative low cost and high availability mean that fossil fuel consumption will likely continue for decades to come. As a result, there is a large amount of scientific research focused on effective methods to remove large amounts of carbon dioxide from the atmosphere and industrial emission sources, and store it safely.

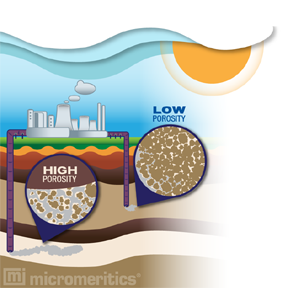

A number of researchers now believe that sequestration of carbon dioxide in deep geological formations shows much promise as a long-term solution for safely storing CO2 that is captured through cleanup efforts. The basic idea involves compressing captured CO2 into a dense fluid and injecting it into a porous deep geological formation, where the rising CO2 fluid is sealed beneath a layer of impermeable cap-rock. Years of experience in the United States with natural gas storage, injecting CO2 for enhanced oil recovery (EOR), Enhanced Coal Bed Methane recovery (ECBM), and the injection of acid gases into saline geological structures have provided an incentive to pursue this promising theory. The U.S. Department of Energy, led by the NETL and Regional Carbon Sequestration Partnerships (RCSP) in partnership with industry and academia, is pursuing a CO2 Sequestration Research, Development, and Demonstration Program. Field tests are currently taking place throughout the U.S. and Canada. Storage areas being investigated include depleted oil and gas reservoirs, unminable coal seams, and deep saline formations. Many of these formations have contained naturally stored carbon dioxide, other gases, and fluids for millions of years and are believed to have the potential to store many years of human-generated CO2. In addition, in the last fifteen years, three large-scale CO2 storage projects in Norway (1996), Canada (2000), and Algeria (2004), have begun operations and reported no safety or health-related incidents.

Even though these formations have the theoretical potential to store human-generated CO2, it is estimated that annually over a billion metric tons must be sequestered in order to make a significant reduction. Many factors have to be studied prior to determination and full-scale implementation of appropriate sequestration sites. Factors such as proper engineering design and monitoring, hydrologic-geochemical-geomechanical processes that govern the long-term storage of carbon dioxide in the subsurface need to be understood. Research scientists require methods to characterize geological materials that help determine the value of the formation as a reservoir.

Since 1962, Micromeritics has supplied analytical tools that determine porosity and surface area, critical measurements needed for the study of potential CO2 sequestration sites. Surface area and mercury porosimetry instruments have been used as necessary tools to characterize the sealing and fluid-transport properties of fine-grained sedimentary rocks under the pressure and temperature conditions of geological carbon dioxide. Pore volume measurements help predict the capacity of a formation. Pore size is an important variable in determining the rate at which CO2 will flow through the formation while filling. Micromeritics' AutoPore Mercury Porosimeter has been used to determine the sealing capacity and pore-throat aperture size distribution on reservoir core samples. Fluid transport experiments can be complemented by the combination of B.E.T. specific surface area data collected on Micromeritics' ASAP 2020 Accelerated Surface and Porosimetry System and mercury porosimetry data. These experiments help reveal significant changes in the transport properties and sealing efficiency of the samples. The ASAP 2020 is also an ideal tool for measuring both micropore and mesopore distributions in coal, therefore providing valuable information for ECBM studies.

Micromeritics' ASAP 2050 Xtended Pressure Sorption Analyzer and Particulate Systems' HPVA-100 High Pressure Volumetric Analyzer are ideal instruments for evaluating the storage capacity of CO2 sorbents at high pressures. The ASAP 2050 is a high-resolution instrument that provides capacity as a function of storage pressure for vacuum to 10 bar. The HPVA extends the characterization to 100 or 200 bar. Both the ASAP 2050 and HPVA allow researchers to evaluate materials under real-world conditions.

International governments, with the aid of the scientific community, must find a way to eliminate the excess CO2 in our atmosphere generated from the burning of fossil fuel. Preliminary data suggest the sequestration of CO2 in geologic formations presents a promising solution. The goal of storing massive amounts of CO2 depends partially on a number of physical characteristics needed for research on each of many geological formations. Micromeritics' expertise and its innovative materials characterization instrumentation have already been, and will continue to be, instrumental in providing important measurements required for carbon dioxide sequestration projects.