Jul 17 2010

PPG Industries’ (NYSE:PPG) aerospace transparencies group has introduced enhanced-design windshields for the Airbus A320 Family that use new technology to improve field performance, reduce maintenance downtime, and lessen the environmental impact of aging and removed windshields.

The PPG Aerospace windshields are available for original-equipment and replacement applications on Airbus A318, A319, A320 and A321 single-aisle airplanes.

“The redesigned windshields incorporate new PRC(R) sealants from PPG Aerospace, a different interlayer and an improved electrical system that combine to provide a superior defense against moisture ingress,” said James Romano, PPG Aerospace global director, commercial transparencies. “By working with operators and Airbus, PPG can use field performance to identify opportunities for improvements that will extend windshield service life.”

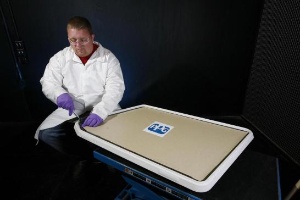

Finisher Anthony Riggins completes fabrication of an enhanced-design windshield for Airbus A318, A319, A320 and A321 aircraft at PPG Industries' Huntsville, Ala., aerospace transparency facility.

Finisher Anthony Riggins completes fabrication of an enhanced-design windshield for Airbus A318, A319, A320 and A321 aircraft at PPG Industries' Huntsville, Ala., aerospace transparency facility.

Two PPG windshield sealants are used to improve moisture resistance, Romano said. New proprietary PR-2060 polyurethane sealant added as an internal sealant and used behind the Z-retainer, he said, has a very low moisture vapor transmission rate compared with previous materials used in such applications. PR-1425CF chromate-free sealant replaces PR-1425 sealant as the outboard moisture seal because of its “green” formulation and faster cure.

To defend against delamination, S-123 urethane bonds the outboard and middle glass plies in place of a urethane-vinyl-urethane sandwich. It has a superior ability to maintain elasticity at low temperatures, preventing cold chipping, and high resistance to moisture damage.

PPG produces windshields and side cockpit windows for Airbus aircraft at its Huntsville aircraft transparencies facility. PPG is also supplier to the KC-45, which is based on the A330 platform.