Siemens VAI Metals Technologies will be installing a new vacuum decarburization plant at the Taiyuan Iron & Steel Co. (Tisco) steel works. The plant will be designed as a double system with a capacity of 180 tons, which will make it the world's largest plant of its type.

The order also includes the engineering, the supply of core components, and services. This secondary steelmaking plant is scheduled to come into production in the middle of 2011, and is part of Tisco's capacity expansion program.

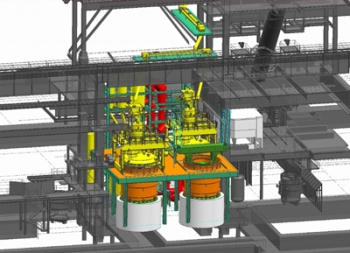

Computer-animated visualization of Siemens VAI's vacuum decarburization plant for the Taiyuan Iron & Steel Co.

Computer-animated visualization of Siemens VAI's vacuum decarburization plant for the Taiyuan Iron & Steel Co.

Tisco is located in Taiyuan, in the Shanxi Province. It is one of China's leading steelmakers and its number 1 high-grade steel producer. The company is currently expanding its range of special steel grades. The new double vacuum decarburization plant will be installed in steel works no. 2, which was also constructed by Siemens VAI, and came into operation in 2006.

Siemens VAI will handle the plant engineering and supply core components. These include a special copper ladle cover, which will be used for the first time with a vacuum decarburization plant. It is intended to substantially reduce the formation of slag skulls on the upper part of the furnace. The new decarburization plant will be installed directly alongside ladle furnace no 2. The project is being jointly implemented with Siemens China, which will be responsible for the vacuum locks and the basic automation.

The main reasons for winning this order were Siemens VAI's expertise in the industry and the good working relationship it has established with Tisco during previous projects. For example, Siemens VAI earlier installed a new hot and cold rolling mill for this Chinese high-grade steel producer.