Applied Materials, Inc. today announced its breakthrough Applied Producer® Eterna™ FCVD™ (Flowable CVD1) system, the first and only film deposition technology capable of electrically isolating the densely-packed transistors in 20nm-and-below memory and logic chip designs with a high-quality dielectric film.

The gaps between these transistors can have aspect ratios of more than 30:1 – five times higher than current requirements – and highly-complex profiles. The Eterna FCVD system’s unique process completely fills these gaps from the bottom up, delivering a dense, carbon-free dielectric film at up to half the cost of spin-on deposition methods – which require more equipment and many additional process steps.

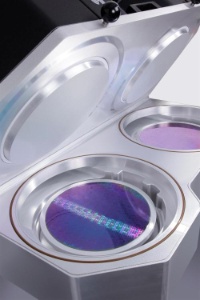

Applied Materials introduces its breakthrough Eterna FCVD system, the first and only technology capable of depositing a high-quality dielectric film between densely-packed transistors in 20nm and below memory and logic chips.

Applied Materials introduces its breakthrough Eterna FCVD system, the first and only technology capable of depositing a high-quality dielectric film between densely-packed transistors in 20nm and below memory and logic chips.

“The need to fill smaller and deeper structures in advanced chip designs creates a physical roadblock for existing deposition technologies. Applied has broken through this barrier today with the introduction of its new Eterna FCVD system – delivering the disruptive technology that can enable the continued progress of Moore’s Law,” said Bill McClintock, vice president and general manager of Applied’s DSM/ CMP2 Business Unit. “With the Eterna FCVD system, Applied continues its decade-long leadership in gap-fill technology, providing a unique, simplified and cost-effective solution for customers to meet the challenges of multiple new chip generations.”

Applied’s proprietary Eterna FCVD process delivers a liquid-like film that flows freely into virtually any structure shape to provide a bottom up, void-free fill. The Eterna FCVD system is installed at six customer sites for DRAM, Flash and Logic applications, where it is integrated on Applied’s benchmark Producer platform.