Based on a formal agreement with IUT Sweden, SECO/WARWICK is pleased to add continuous aluminum log/billet homogenizing to the scope of products available to the global extrusion market.

This multi-zone vertical airflow furnace technology is incredibly flexible. The furnace can process billets of different alloys and diameters without leaving empty saddles.

The control system manages the walking beam cycle time and air temperature set points to ensure that furnace throughput is optimized and required product quality is achieved.

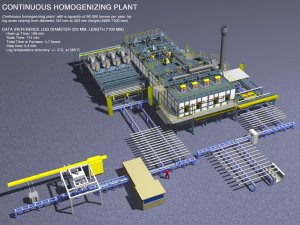

The fully equipped plant consists of the furnace, cooling section, and loading/unloading equipment. The operation is controlled completely automatically, thus minimizing the need for operator input. This advanced technology offers reduced cycle times, reduced energy consumption and improved end product parameters.

On-going technical cooperation between the two companies assures that the design will remain on the cutting edge of technology.