Oct 25 2010

Being the right size and existing in the limbo between a solid and a liquid state appear to be the secrets to improving the efficiency of chemical catalysts that can create better nanoparticles or more efficient energy sources.

When matter is in this transitional state, a catalyst can achieve its utmost potential with the right combination of catalyst particle size and temperature, according to a pair of Duke University researchers. A catalyst is an agent or chemical that facilitates a chemical reaction. It is estimated that more than 90 percent of chemical processes used by industry involve catalysts at some point.

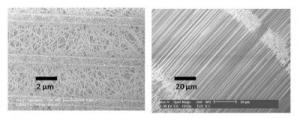

These are nanotubes

These are nanotubes

This finding could have broad implications in almost every catalyst-based reaction, according to an engineer and a chemist at Duke who reported their findings on line in the American Chemical Society's journal ACS-NANO. The team found that the surface-to-volume ratio of the catalyst particle – its size -- is more important than generally appreciated.

"We found that the smaller size of a catalyst will lead to a faster reaction than if the bulk, or larger, version of the same catalyst is used," said Stefano Curtarolo, associate professor in the Department of Mechanical Engineering and Materials Sciences.

"This is in addition to the usual excess of surface in the nanoparticles," said Curtarolo, who came up with the theoretical basis of the findings three years ago and saw them confirmed by a series of intricate experiments conducted by Jie Liu, Duke professor of chemistry.

"This opens up a whole new area of study, since the thermo-kinetic state of the catalyst has not before been considered an important factor," Curtarolo said. "It is on the face of it paradoxical. It's like saying if a car uses less gas (a smaller particle), it will go faster and further."

Their series of experiments were conducted using carbon nanotubes, and the scientists believe that same principles they described in the paper apply to all catalyst-driven processes.

Liu proved Curtarolo's hypothesis by developing a novel method for measuring not only the lengths of growing carbon nanotubes, but also their diameters. Nanotubes are microscopic "mesh-like" tubular structures that are used in hundreds of products, such as textiles, solar cells, transistors, pollution filters and body armor.

"Normally, nanotubes grow from a flat surface in an unorganized manner and look like a plate of spaghetti, so it is impossible to measure any individual tube," Liu said. "We were able to grow them in individual parallel strands, which permitted us to measure the rate of growth as well as the length of growth."

By growing these nanotubes using different catalyst particle sizes and at different temperatures, Liu was able to determine the "sweet spot" at which the nanotubes grew the fastest and longest. As it turned out, this happened when the particle was in its viscous state, and that smaller was better than larger, exactly as predicted before.

These measurements provided the experimental underpinning of Curtarolo's hypothesis that given a particular temperature, smaller nanoparticles are more effective and efficient per unit area than larger catalysts of the same type when they reside in that dimension between solid and liquid.

"Typically, in this field the experimental results come first, and the explanation comes later," Liu said. "In this case, which is unusual, we took the hypothesis and were able to develop a method to prove it correct in the laboratory."