The new Hyperform HPR family of reinforcing additives from Milliken provides processors with a new option for making high performance polypropylene parts with low weight.

Hyperform HPR-803 is intended primarily for the automotive sector. Milliken plans future innovations aimed at applications in automotive, appliances and elsewhere.

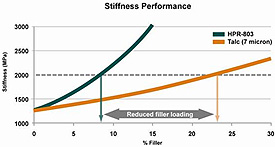

Graphs show how Hyperform HPR-803 synthetic fibre has a much greater effect on part stiffness than talc filler.

Graphs show how Hyperform HPR-803 synthetic fibre has a much greater effect on part stiffness than talc filler.

"We envisage HPR-803 being used mainly in automotive applications, but are not limiting our project scope," says Adam Watson, in charge of marketing for the Hyperform HPR range. "It enables the production of polypropylene compounds that have mechanical performance similar to or better than mineral filled compounds, but at lower weight."

HPR-803 fibers have a high aspect ratio of around 40:1. "We expect PP compounds containing HPR-803 to replace talc-filled types and possibly other non-PP-based materials too," says Watson. "Tests have also demonstrated that HPR-803 works very well in combination with talc, giving processors and end users the opportunity to convert to the new technology in a step-by-step fashion."

Hyperform HPR-803 is added at levels typically one third of those required for talc (fig 1). This means parts will be lighter, by up to 15%, and cars may use less fuel and have lower carbon dioxide emissions.

Several projects currently underway demonstrate the value of Hyperform HPR-803 in producing lightweight parts with high stiffness. Watson cites development trials with an injection molded bumper support. "Milliken demonstrated that a compound containing nine percent of HPR-803 could deliver 10% weight savings over a 20% talc-filled compound, and still maintain dimensional, stiffness and impact requirements," he says.

HPR-803 also enabled the parts to be produced with a shorter cooling time and hence lower overall cycle time. Furthermore, test parts demonstrated excellent performance under thermal stability performance testing (fig 2).

The value proposition does not stop at energy savings - aesthetics are also improved with Hyperform HPR-803. The natural color of the additive is whiter than talc, so processors can cut down on pigment usage to get the color they want. Parts containing the new reinforcing additive exhibit a noticeably better surface finish and also higher weather resistance than glass fiber reinforced PP parts with similar mechanical properties.

For compounders, Hyperform HPR-803 is easier to handle than chopped glass and therefore presents less of a health and safety issue. Compounds containing HPR-803 exhibit good flow characteristics, and can be handled in the same way as other PP compounds.

Recycled material exhibits little loss of mechanical properties, unlike glass filled compounds. Wear on equipment is reduced at all stages of processing. Early data indicate that there may be energy savings realized from compounding HPR-803, compared with talc and glass fiber alternatives.

Hyperform HPR-803 is available directly from Milliken as a free-flowing powder, and can be incorporated during compounding via a side-feeder. Milliken is working with compounders around the world to develop compounds and masterbatches designed for various applications.