Market leaders in temperature controlled microscopy, Linkam Scientific Instruments announce the use of their temperature controlled tensile stage by the Mather Group at Syracuse University.

Patrick Mather is Professor of Biomedical and Chemical Engineering at Syracuse University. His research group focuses on functional materials: in particular, the development of polymeric and hybrid materials with prescribed functionality beyond traditionally passive mechanical roles. The applications range from medical to structural materials technology. Utilizing the core experimental strengths of Syracuse Biomaterials Institute, such as polymer synthesis, rheology & processing, morphological analysis, quantitative thermal analysis and mechanical testing, the group pursues the development of these functional polymeric systems.

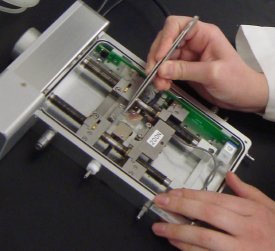

Loading a sample in the Linkam TST350 tensile stage.

Loading a sample in the Linkam TST350 tensile stage.

Professor Mather selected the Linkam TST350 tensile stage for his micro/nanoscale mechanical property studies because it provided accurate temperature and torque control while having open architecture for modification for more advanced measurements. With graduate students Erika Rodriguez and Xiaofan Luo, protocols for the evaluation of self-healing polymeric films were developed. Typically, the stage is used with a 200N load cell to uniaxially stretch samples to a displacement of 10 mm (corresponding to a strain of 60% at a displacement rate of 0.1 mm/s (0.6%/s) at RT. The study is repeated after thermal annealing of the sample which causes the sample to fully recover its original shape. This is to analyze whether the mechanical properties of the sample were compromised from the first stretch. Further custom experiments are also performed using a double edge notch punch. Data from all the experiments has recently been published by the ACS: ACS Appl. Mater. Interfaces, 2011, 3 (2), pp 152-161.

The Linkam TST350 enables the study of the tensile properties of samples relative to their temperature. Mounted on an optical microscope or Linkam Imaging Station, it is possible to capture high resolution images of the structural changes. The TST350 is built with two precision ground stainless steel lead screws to maintain perfect uniform vertical and horizontal alignment. Sample jaws move in opposite directions to maintain sample in both reflected or transmitted microscope fields of view. This also means other transmitted techniques such as x-ray, needed for internal observation of sample structure can be used. Importantly for environmental control, the sample chamber is gas sealed and can be controlled with various gases via the gas valves built onto sides of the stage.