Currently, car makers are looking for innovative welding process to produce perfect weld seam. An innovative camera system addresses this need by studying the thermal images to assure a perfect weld.

The welding head fitted on the arm of a robot moves along the metal parts. The place where the laser penetrates, the metal turns to red hot and this process remains for a few seconds. Now, the car’s door fame and outer door panel are precisely welded. The weld seam is seen only on one side of the car door and remains invisible on the other side. This results in a perfect weld, which is the dream of all car manufactures.

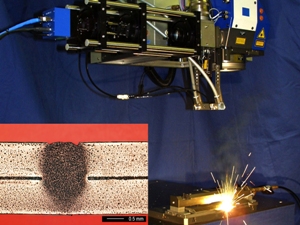

In the new surface welding process the laser produces a perfect seam. Bottom left: Weld seam profile – the penetration depth is controlled without damaging the bottom surface.

In the new surface welding process the laser produces a perfect seam. Bottom left: Weld seam profile – the penetration depth is controlled without damaging the bottom surface.

A new process called controlled partial penetration welding has been developed by researchers at the Fraunhofer Institute for Physical Measurement Techniques IPM. The scientists have found that the innovative welding process does not allow the laser to burn all the layers of metal. It limits the penetration of weld seam till the lower sheet and prevents damage on the bottom surface. Until now, it has not been possible to exactly control the welding process and create a joint based on strength requirements. To address this issue, the researchers used a new camera system that produces temperature images. The camera features cellular neural networks and a tiny processor is included in each pixel. These features accelerate the analysis of separate images. The camera identifies the depth of laser penetration into the metal sheets. The images indicate a hot region when the laser burns and melts the metal sheets. A cooler point can be visualized when the melt pool arrives at the gap between the lower and upper sheets and interrupts the heat conduction process. This point is called full penetration hole, which determines the depth of penetration into the lower sheet. The innovative camera system has a capacity to analyze nearly 14,000 images per second.

Researchers at Fraunhofer IPM have joined with scientists from the Stuttgart University’s IFSW Institut für Strahlwerkzeuge and Dresden University’s Institut für Grundlagen der Elektrotechnik und Elektronik (IEE) to design a prototype that manages the surface welding method, providing significant benefit to car manufacturers. The prototype does not allow zinc vaporization at the bottom of the weld.