New automotive production technologies will be presented by the Fraunhofer scientists at the Laser 2011 event. Current auto makers are mainly concerned about energy conservation and it is shown that laser technology helps to achieve this.

Lasers could be used for manufacturing powerful engines, highly efficient engines and for processing fiber-composite made lightweight auto parts. Scientists will explain the use of lasers in saving energy, money and time.

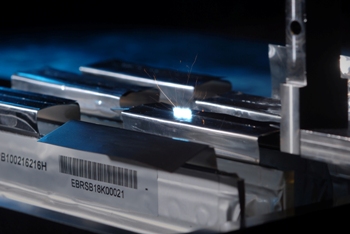

The welding of aluminum and copper battery lugs with a disk laser for the production of battery systems used in electric vehicles.

The welding of aluminum and copper battery lugs with a disk laser for the production of battery systems used in electric vehicles.

Automotive manufacturers are increasing the use of fiber-reinforced plastics for reducing weight. The plastics are lighter than metal in the range of 30 to 50%. The main drawback in using the fiber-reinforced plastics is that the processing of these materials is difficult. The equipment used to cut and drill these materials gets damaged rapidly and traditional assembly methods applied for metal components are also not suitable for the lightweight components. To overcome this problem, laser is the best alternative to process fiber-reinforced plastics without any damage. It can also connect the materials through a welding process.

The tool design can be done with the help of lasers in an automatic, highly variable and efficient manner. Till now, a negative pattern for developing the design was imprinted out of steel tools that are utilized in injection molding. This is a complex process and consumes more time. However, with the use of lasers the steel surface can be patterned rapidly and in different varieties.

Laser technology can also help to reduce friction in electric engines. Ceramic coatings with high performance are required to produce less friction and they are also smooth and have wear resistance characteristics. However, the production of coated metal parts is more costly. A cost-effective and quick method has been developed by the Fraunhofer researchers. The new method allows coating of components with ceramic nano-particles and later they undergo laser treatment. This process has been currently used for bearings and gear wheels.

Another important use of the lasers is production of highly efficient electric batteries. At present, Fraunhofer engineers and scientists are working on several methods to develop low cost and durable batteries. One way is that the efficiency of batteries can be increased by expanding the electrodes’ surface area with suitable coating and the other solution is to analyze and perfect the production processes. Lasers help to produce stable connections between electrodes with high electrical conductivity.