A new 3-minute video highlighting the versatility of the Parsum IPP 70 In-line Particle Probe is now available on the Malvern Panalytical website.

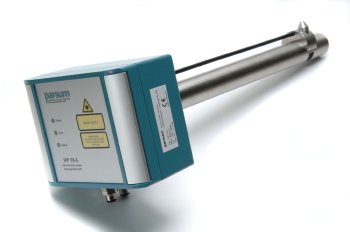

Designed to measure continuously the size, size distribution, and velocity of granular particles, directly in the process, the Parsum In-line Particle Probe (IPP) is a valuable tool for process development and automated production. It has applications in many sectors including the food, chemical and pharmaceutical industries.

'Real-time particle size measurement for granulation optimization' is also the subject of a Malvern Panalytical poster at the 5th International Granulation Workshop in Lausanne, Switzerland in June 2011. This will discuss how monitoring process granulation endpoints using real-time on and in-line analyzers can aid the pharmaceutical industry in the successful implementation of the Process Analytical Technology (PAT) initiative, while maintaining efficient manufacture of materials.

The Parsum probe uses patented spatial filter velocimetry to measure particles in the size range 50-6000 µm travelling at velocities of between 0.01- 50 m/s. Easily fitted in line, or into a process vessel, it can be applied in both gaseous and liquid media and is especially well suited to granulation applications, both high shear and fluidized bed. Parsum software drives analysis and streamlines the automation of plant control to deliver enhanced product quality and reduced variable cost. Remote system access makes possible easy observation and data reporting.

Malvern Panalytical has extensive experience and expertise in sectors as diverse as cement production and pharmaceutical drug discovery, providing a range of systems for laboratory and in-process analysis.