The Swiss Federal Laboratories for Materials Science and Technology, Empa, has developed a breakthrough technology for producing flexible copper indium gallium (di)selenide semiconductor (CIGS) solar cells with a record efficiency of 18.7%.

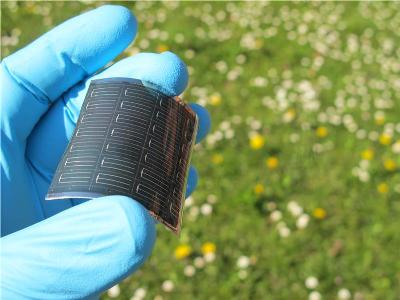

Flexible CIGS solar cells developed at Empa

Flexible CIGS solar cells developed at Empa

Empa scientists achieved the high efficiency by controlling the grading of the energy band gap in the CIGS cells. Lightweight, flexible solar cells on plastic foils or polymer films can lower the cost of solar electricity due to their low cost of manufacture. But polymer films need a lower temperature during the absorber layer deposition process, which leads to a lower efficiency.

Empa researchers at the Laboratory for Thin Film and Photovoltaics have been focusing on reducing the CIGS layer’s deposition temperature on flexible and glass substrates. They have progressively increased the efficiency on flexible substrates to the current 18.7%. This efficiency is nearly equivalent to that of CIGS cells on glass. They reduced the recombination losses related to photo-generated charge carriers. To achieve this they developed a novel growth process, which included controlling of indium and gallium evaporation flux during the evaporation process stages.

The novel technology developed by Ayodhya N. Tiwari and the research team at Empa also yielded a high 17.7% efficiency on steel foil. The process did not utilize nitride or diffusion oxide barrier layers that are normally used for such high high-temperature processes. The research demonstrated the potential of the technology for application on cost-effective metal foils leading to a reduction in the cost of production.

“Nature Materials” has published the results of this low-temperature deposition technology.