Germany’s Badische Stahlwerke has chosen Siemens VAI to upgrade its wire rod rolling process. Badische Stahlwerke’s wire rod rolling facility manufactures the foundation material for concrete reinforcing bar.

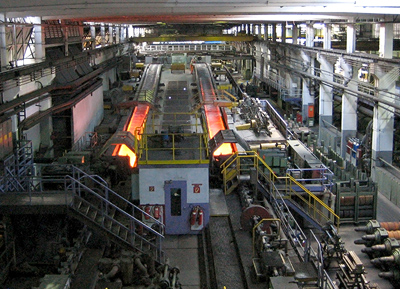

Wire rod mill of Badische Stahlwerke GmbH (BSW) in Kehl, Germany. The mill will be thoroughly modernized by Siemens. Credit: BSW

Wire rod mill of Badische Stahlwerke GmbH (BSW) in Kehl, Germany. The mill will be thoroughly modernized by Siemens. Credit: BSW

Siemens will modernise the facility in three phases during the period between 2011 and 2014. The facility will be shutdown every year as per schedule to facilitate modernisation.

In the first phase, the mill’s current automation system that comprises 13 roughing and intermediate stands, will be replaced by Siemen’s Siroll automation system, which is based on the Seimens PCS7 software. During the second phase, Siemens will set up two rod outlets, each of which will have a six stand and four stand Morgan No-Twist mill. Siemens will also provide trimming shears that run on high speed, Morgan Stelmor conveyors, 10 Morgan Intelligent Pinch rolls, vertical coil handling system and Morgan High Speed Laying Heads. For the third phase, the new systems will be fitted in the mill and will be commissioned by 2014. The new systems promise a rod speed of 110 m/sec and production of a coil in every 20 secs. This will lead to a production rate of 300 t/hr.

Badische Stahlwerke will plan and execute all the related infrastructure and will also install other systems like the water system. However, Siemens will erect and commission all the electrical and mechanical equipment through a turnkey project.