Chinese steel producer Shanxi Zhongyang Iron and Steel Company Ltd. (ZISCO) contracted with Siemens VAI Metals Technologies to add a high-speed mini finishing mill to each of its three rod mills. The new mills will be located in a suburb of Zhongyang County, Shanxi Province, China.

This will almost double the mills' production speed. Commissioning is expected in late 2012.

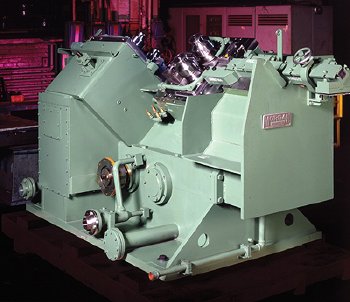

High-speed mini finishing mill for long-product rolling mills from Siemens VAI Metals Technologies.

High-speed mini finishing mill for long-product rolling mills from Siemens VAI Metals Technologies.

After the three finishing mills begin operation, the annual output of each mill will increase to 700,000 tons from 500,000 tons and thus considerably enhance ZISCO´s production capacity. Meanwhile, with the three high-speed mini finishing mills, the company will also be able to produce small sizes, with one plant producing rod from 5.5 mm to 10 mm and rebar from 8 mm to 10 mm, and in the other two mills, rod from 5.5 mm to 16 mm and rebar from 8 mm to 14 mm. Speeds are guaranteed at 105 meters per second. The scope of supply from Siemens VAI also includes guides. The electrical and automation package will be supplied by Siemens Limited China, utilizing the standard Siroll LR solution platform for long-product rolling mills and including the medium voltage drive.

A mid-size private company established in 1985, ZISCO is an integrated mining, steel making and power generation company, which produces carbon grade rod and rebar for the Chinese construction market. It produced 3.6 million tons of steel wire in 2009.

About Siemens Metals Technologies Business Unit

The Metals Technologies Business Unit (Linz, Austria), part of the Siemens Industry Sector, is one of the world's leading suppliers of plant construction and engineering in the iron and steel industry as well as in the flat rolling segment of the aluminum industry. The Business Unit offers a comprehensive product and service portfolio for metallurgical plants and equipment as well as integrated automation and environmental solutions covering the entire lifecycle of plants