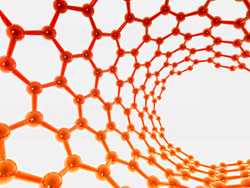

A research programme titled, ‘Nano packaging technology for interconnect and heat dissipation,’ funded by the EU and conducted by the project management team at Thales Research and Technology,13 companies, universities and research institutes is in the process of developing polymer fibres, adhesives, carbon nanotubes and greases to reduce heat generation in electronic devices such as laptops and GPS systems.

© Shutterstock

© Shutterstock

Use of the latest technology, which focuses on increasing the power of electronic devices simultaneously increases the amount of heat generated in the device. According to experts, overheating can potentially reduce the speed of processing in electronic devices in the future. Latest technologies like 3D chips will only increase heat generation.

While many solutions towards reducing heat dissipation have been analysed by various research programmes, the most effective solution lies in addressing the thermal interfaces, which are located between the chip’s core and packaging and through the packaging to the cooling system. These locations contain about 40-50% of thermal resistance. If thermal resistance can be reduced here, then the effectiveness of the cooling system can be enhanced thus enabling the chips to run at the same temperature with a greater processing power. The programme, which has received around €7 million from the EU is developing various materials such as adhesives, greases that are thermally conductive. While some materials are closer to reaching the market for commercial use, others are in their developmental stages. Examples of these materials include grease developed by the Austrian project partner Electrovac from graphitised carbon nano-fibres and micro spheres, a gold nano-sponge where the sponges are placed a few nanometres away and carbon nanotubes that have high thermal conductivity.