Researchers at the Rice University and Schlumberger’s subsidiary M-I SWACO, a drilling fluid supplier based in Texas, have synthesized functionalized graphene oxide to eliminate the blockage of oil-generating holes in newly drilled oil wells.

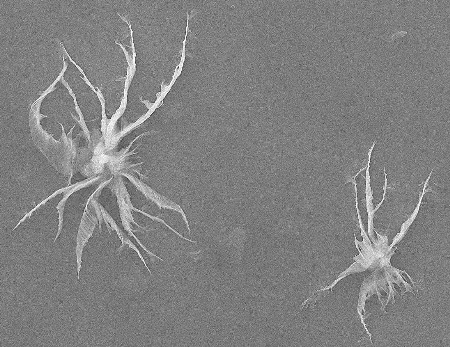

Microscopic, star-shaped flakes of functionalized graphene oxide plug holes in pores in a test of the material's ability to serve as a filter cake in fluids used to drill oil wells. The single-atom-thick flakes of treated carbon are pliable but among the strongest materials known. (Credit Tour Group/Rice University)

Microscopic, star-shaped flakes of functionalized graphene oxide plug holes in pores in a test of the material's ability to serve as a filter cake in fluids used to drill oil wells. The single-atom-thick flakes of treated carbon are pliable but among the strongest materials known. (Credit Tour Group/Rice University)

The partnership between Rice University and M-I SWACO was established two years ago when the lab received funding from the company for the follow-up research on graphene additives for enhancing drilling fluids called muds that are utilized in oil well drilling. Since then, the researchers have been refining the graphene material to address some of its issues in oil well drilling. They found that pliable, microscope and star-shaped graphene flakes are capable of forming lightweight and thin filter cakes.

In the oil-producing process, these drilling fluids are injected downhole to clean the drill bits and take out the cuttings. Conventional clay-enhanced muds use differential pressure to create a filter cake over the wellbore. This filter cake prevents the drilling fluids from entering and the oil from flooding out the small, oil-generating holes. During the removal of the drill bit and drilling fluid, the oil generated inside the hole begins to come out into the well by clearing the residues of the filer cake. However, this clay cannot be displaced sometimes, resulting in the reduction of oil productivity.

The insolubility of pristine graphene in water makes it incompatible for water-based muds. Although graphene oxide has better solubility in fresh water, its tendency to congeal in saltwater, the cornerstone for many muds, is a problem. According to the researchers, the solution is the esterification of graphene oxide flakes with alcohol, resulting in a functionalized graphene oxide that eliminates the formation of clots with salts.

The researchers discovered optimally functionalized graphene oxide that is a mix of pulverized graphene oxide for strength and large flakes through a sequence of standard tests of the American Petroleum Institute. A mud containing 2% of functionalized graphene oxide has produced a filter cake having an average width of 22 µm, a dimension much lower than the 278- µm filter cake produced by conventional muds. The small size of the filter cake made of graphene oxide allows a drill bit to rotate freely. Moreover, the filter cake is eco-friendly, as the graphene oxide can be reduced to graphite by common bacteria. Graphene oxide clogged holes are much smaller than the original diameter of the flakes by folding.