The aerospace coatings group of PPG Industries has announced the commercialization of first-of-its-kind electrocoat-application primer called AEROCRON for worldwide airframe producers and subcontractors. The primer can be applied over general-aviation, military and commercial aircraft components.

Graphic: Business Wire

Graphic: Business Wire

The Global Platform Director for PPG’s Aerospace Coatings, Mark Cancilla stated that AEROCRON electrocoat primer offers superior corrosion resistance when compared to traditional spray primer due to the fact that electrocoating improves part coverage. He added that the electrocoat primer eliminates wastage and workers exposure to overspray, while decreasing primer weight for improved aircraft fuel economy.

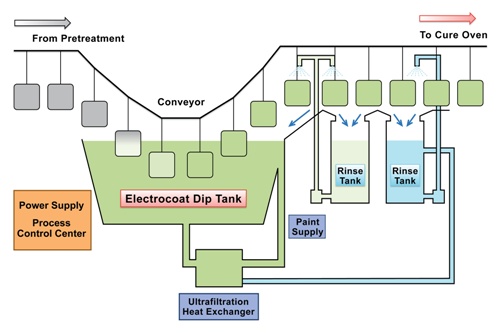

Primer coating is for protecting metal aircraft structures from corrosion. In conventional processes, primers are usually sprayed over the metal components. However, in the electrodeposition or electrocoating process, metal components are immersed into an electrically charged container of primer.

Cancilla further said that PPG used its expertise in e-coat process and knowledge in aerospace coatings to synthesize AEROCRON electrocoat primer for fulfilling the application requirements of the manufacturers of aircraft structures and maintenance needs of aircraft operators and airlines.

Robin Peffer, who serves as senior research chemist at PPG’s Coatings Innovation Center, stated that the electrocoat primer provides homogenous coating even on intricate parts and offers significant savings in aircraft operations over a period by reducing weight.

The Technical Projects Manager of PPG aerospace coatings for Europe, Andreas Tolz is responsible for the commercialization of AEROCRON electrocoat primer in the European market. According to Tolz, the electrocoat process is a ‘green’ option to aircraft producers and subcontractors, as it can be completely automated and reduces material wastage.