Researchers from the National Institute of Standards and Technology (NIST) have devised a novel software to measure the friction of graphene, a one-atom-thick carbon material.

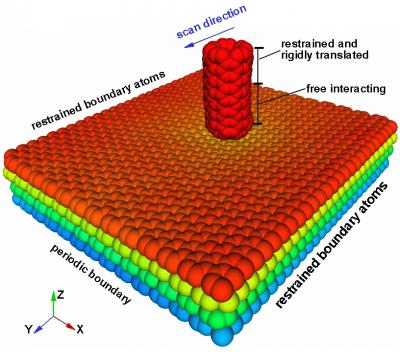

NIST software simulates the tip of an atomic force microscope moving left across a stack of four sheets of graphene. Research using this software indicates that graphene's friction is reduced as more layers are added to the stack. (Credit: A. Smolyanitsky/NIST)

NIST software simulates the tip of an atomic force microscope moving left across a stack of four sheets of graphene. Research using this software indicates that graphene's friction is reduced as more layers are added to the stack. (Credit: A. Smolyanitsky/NIST)

According to the NIST researchers, graphene sheets decelerate an object that slides over their surface but get more slippery when are stacked up. Alex Smolyanitsky, who developed the modeling program, stated that these findings are helpful for people who intend to utilize graphene as a component of flexible electrodes or as a solid-state lubricant. Smolyanitsky added that the NIST simulation demonstrates friction in graphene on an atomic scale for the first time.

The NIST program uses a molecular dynamics technique for simulating atomic force microscopy (AFM). The software measures what occurs during the movement of a simulated AFM tip along a stack of one to four sheets of graphene at various scanning rates. The scientists discovered that the material deflects beneath and around the AFM tip. The localized, short-term deflection generates resistance or rolling friction. These findings of NIST are in line with the result of recent graphene studies conducted by other researchers, but offered new quantitative data.

The NIST experiment demonstrates the reason behind reduced friction with respect to the addition of each graphene sheet to the stack. When the layers are few, the deflection of the topmost layer is more, which in turn increases the friction per AFM contact force unit. When more layers of graphene are added, the top layer of the stack turns out to be more slippery and less yielding. However, in three-dimensional materials, rolling friction and deformation have no impact on friction, which is rather caused by heat generated by the moving tip.