A critical review of claims that there are materials harder than diamond

"Diamond is not the hardest material anymore". This remarkable claim was first made at the International Symposium on Plasma Chemistry held in Prague, Czech Republic, in 2 -6 August 1999 by Professor Stan Veprek of the Technical University, Munich.

Speaking at this conference, Professor Veprek made the astonishing announcement that, "we report on the first preparation of a material with a Vickers microharness equal to or even higher than that of diamond."

The hard material he referred to is a nano-composite coating. These coatings were deposited on to a softer material, such as steel, with the intention of improving performance of engineering and industrial applications such as cutting tool bits.

Hard coatings are conventionally applied to softer substrates, but what makes nanocomposite coatings so special is that by making the grain size of the coating extremely small, and with the addition of very small amounts of silicon nitride to glue the grains together, the hardness of such a coating can be considerably increased compared to conventional coatings.

In his initial work, Professor Veprek claims to have measured the Vickers hardness of several coatings obtaining results ranging from 91 GPa up to 138 GPa. In comparison, the hardness of diamond is generally accepted to be about 100 GPa. The hardest coatings made by industrial and research processes is usually accepted to be of the order of 60 GPa and so it is not surprising that there has been considerable doubt about the accuracy of Professor Veprek's results.

These questions have arisen because the results so far, have not been repeated by any other research group. The problem is further compounded by the apparent loss in hardness of the original samples due to long term storage so independent testing is no longer a possibility. Furthermore, it appears that no more samples displaying these extraordinary hardness values have been forthcoming from Professor Veprek and his co-workers since 1999, despite his many invited appearances at internationally recognised conferences on this and related topics.

There are widely accepted techniques for the determination of the hardness of materials and coatings. They involve the direct measurement of the area of a residual impression made in the sample surface by a pyramidal indenter, or an instrumented approach where the depth of penetration of the indenter into the specimen is measured and the area of contact calculated from the known geometry of the indenter shape. In his original work, Professor Veprek used both techniques.

In 2005, it was established that Professor Veprek and his colleagues made significant errors in their analysis of the instrumented data. In addition the supporting SEM image published in their ground breaking work was incorrectly sent to the publisher. Since then, numerous papers have appeared from Professor Veprek's group in support of this original work based upon theoretical and finite element analyses.

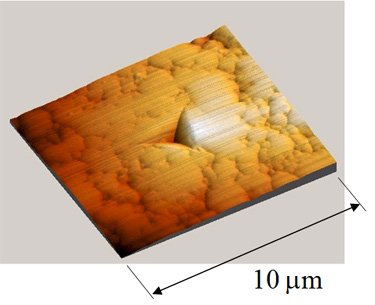

AFM image of a typical super-hard nanocomposite film showing the residual impression made in the surface by a diamond pyramid indenter. Measurements of the depth of penetration by a nanoindenter can be used to calculate the hardness of the coating. (Fischer-Cripps Laboratories Pty Ltd)

AFM image of a typical super-hard nanocomposite film showing the residual impression made in the surface by a diamond pyramid indenter. Measurements of the depth of penetration by a nanoindenter can be used to calculate the hardness of the coating. (Fischer-Cripps Laboratories Pty Ltd)

This latter work has recently been reviewed by a small team of internationally-recognised experts with the result that many of the conclusions drawn cannot be supported. For example, just some of the issues that have been recently uncovered are:

- Professor Veprek used the Hertz equations from an engineering text book which contained inappropriate boundary conditions for his application,

- Inconsistent values of elastic modulus were used to calculate the yield strength for inclusion in the finite element model,

- Professor Veprek used an inconsistent definition of hardness in comparing his finite element results with those obtained by experiment.

The comprehensive review concluded by examining the latest theoretical models and analysing the previously published data correctly. It was found that the hardness of Professor Veprek's original coatings appeared to be of the order of 50 to 60 GPa and that the upper limit possible for such a material is of the order of 70 GPa.

Editors Notes

The review detailed above has been accepted for publication in the Philosophical Magazine and will be presented at the ICMCTF conference in San Diego in April 2012.

The presentation will be delivered by Dr. Tony Fischer-Cripps on behalf of his co-authors Professor S.J. Bull and Dr N. Schwarzer., details below:

"Critical Review of Claims for Ultra-Hardness in Nanocomposite Coatings"

A.C. Fischer-Cripps*, Fischer-Cripps Laboratories Pty Ltd, Australia [email protected]

S. J. Bull, Newcastle University, School of Chemical Engineering and Advanced Materials,

Merz Court, Newcastle upon Tyne, UK.

[email protected]

N. Schwarzer, Saxonian Institute of Surface Mechanics SIO, 18569 Ummanz / Rügen,

Germany

[email protected]

Professor Veprek is scheduled to make a rebuttal presentation to these issues at the conference, the current presentation details are provided below:

"Preparation and Characterization of Super- and Ultrahard Nanocomposites"

S. Veprek ([email protected]), M. Veprek-Heijman, Technical University Munich, Germany

A.S. Argon, Massachusetts Institute of Technology

Abstract

In the first part of our presentation, we shall identify several serious inconsistencies and methodological mistakes in the presentation of Fischer-Cripps as far as we can identify them presently from the press release on his home page and from a manuscript available to us [1].

We shall further show that the hardness of the nc-TiN/a-Si3N4/TiSi2 of about 80 to 100 GPa reported in our earlier papers (see [2] for a review) is supported by our indentation measurements as well as by scanning electron micrographs of the remaining indentations.

We shall further briefly outline the issue of the reproducibility of the preparation of these unique materials.

The emphasis of our presentation will be, however, on the future ways which will assure the reproducible preparation of nc-TiN/a-Si3N4 and related nanocomposites in dedicated laboratory apparatuses as well as in large-scale industrial coating equipment, which will assure achieving high hardness, high resistance against brittle fracture, high thermal stability and oxidation resistance.

[1a] www.ibisonline.com.au/IBIS_News/PressReleaseAug11.pdf

[1b] A.C. Fischer-Cripps et al., submitted, as quoted in Ref. [1a]

[2] S. Veprek et al., Thin Solid Films 476 (2006) 1

Further details can be viewed online at;

http://www2.avs.org/conferences/ICMCTF/pdfs/abstracts.pdf Pages 81, 94

Disclaimer: The views expressed here are those of the author expressed in their private capacity and do not necessarily represent the views of AZoM.com Limited T/A AZoNetwork the owner and operator of this website. This disclaimer forms part of the Terms and conditions of use of this website.