Packaging, insulation, and impact protection are examples of commercial uses of polymer foams. Depending on the intended application, the properties required of these foams can differ greatly. In the journal Angewandte Chemie, a team of German, Irish, and French researchers led by Cosima Stubenrauch at the University of Stuttgart has now introduced a new method for the controlled production of structured foams. Their technique is based on the polymerization of foamed emulsions of oil in water.

Not all foams are equal: a kitchen sponge, for example, is not the same as a piece of Styrofoam packaging. Different applications make different demands on a foam, which has led to efforts to control the properties of foams in a targeted fashion. In addition to a foam's chemical composition, its structure also plays an important role. The property profile of a foam depends on the number and size of the pores, whether the pores are closed off or connected, and the thickness of the polymer supports between the pores. "The high complexity of conventional production processes, which generate foams from polymer melts and blowing agents, makes control over the morphology and properties of the product a big challenge," explains Stubenrauch.

An alternative approach involves the use of microscopically small templates to force the foam into the desired structure. For example, tiny droplets of water can be finely dispersed (emulsified) in a solution of monomer, then removed after the polymerization is complete. Another process uses particles to stabilize air bubbles in the reaction mixture.

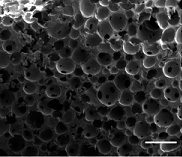

Stubenrauch's team has now introduced a new concept for the synthesis of macroporous polystyrene foams: the polymerization of foamed oil-in-water emulsions. Styrene (the "oil phase") is first emulsified in an aqueous phase. Afterward, the emulsion is stabilized with an anionic surfactant and foamed with nitrogen. This forms bubbles surrounded by tightly packed drops of emulsion. In the third step, the polymerization is initiated by irriadiation with UV light. The drops of emulsion dissolve away, while the structure of the foam-that of the template-is maintained.

The resulting polymer foams contain pores that are partially interconnected through "windows". "While the high density of the polymer and the strong bonds provide good mechanical stability, the presence of the windows allows air, fluids, or other materials to flow through the foam," says Stubenrauch. "Control over these properties is desirable for many applications, such as supports, filter agents, or biologically inspired scaffolding. This production technique is simple and versatile and represents a highly promising alternative to other template-based synthetic methods."