Siemens VAI Metals Technologies announced that it has secured an order for a new compact steelmaking plant from a Mexican steel producer, Talleres y Aceros (Tyasa). The new plant will be located at Tyasa’s Ixtaczoquitlan site and will have a production capacity of 1.2 million tons of low-, medium- and high-carbon steel annually.

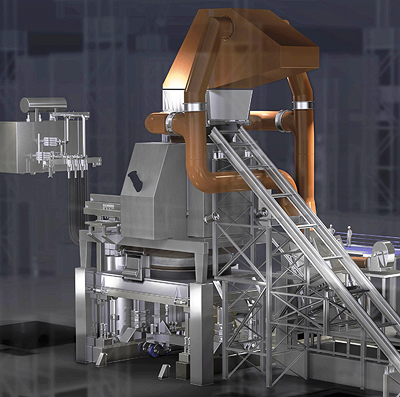

The world's first Quantum electric arc furnace is being constructed for Tyasa, a Mexican steelmaker.

The world's first Quantum electric arc furnace is being constructed for Tyasa, a Mexican steelmaker.

The key equipment of the facility is Siemens’ newly developed Simetal EAF Quantum electric arc furnace with a tapping weight of 100 t. The order also includes supply of a combination continuous caster and secondary steelmaking facilities, which include a 100 t double vacuum degassing facility and a double ladle furnace with 100 t capacity. With the new compact steelmaking facility, Tyasa will enhance its production capacity as well as expand its product range. The project is expected to be completed by the mid of 2013.

The Simetal EAF furnace integrates an optimized tapping system, an innovative tilting concept for the lower shell, a preheating system and established shaft furnace technology components with a novel scrap charging method. This helps to achieve tap-to-tap times of 36 minutes. The furnace consumes less electricity, which is just 280 kWh per ton, than a conventional electric arc furnace. Another advantage of the furnace is lower consumption of oxygen and electrodes. All these together contribute to the decrease in the specific conversion cost for steel production by approximately 20 %. In addition, overall CO2 emissions can be minimized by about 30% per ton of steel when compared to conventional electric arc furnaces.

The project also includes installation of a double circuit water cooling system and a dry dedusting system with an induced draught fan, an automated pulse-jet-type filter-bag house, a quenching tower and evaporation cooler. The dedusting system will remove offgases from the furnaces and the material handling system.