Double-coated flame retardant tapes from Polyonics are suitable for bonding materials, which are under the exposure of extremely high temperatures and adverse production conditions such as places where the spread of fire needs to be stopped.

Chemical Mechanisms that Help Retard Burn Cycle

Chemical Mechanisms that Help Retard Burn Cycle

Polyonics’ flame retardant tapes provide more stiffness than transfer adhesives, thus enabling auto-application and die-cutting when integrated with liners. These tapes utilize the company’s proprietary FlameGard technology to efficiently control the flaming process.

The double-coated RoHS and REACH tapes have resistance against chemicals commonly used in electronics production and retain their dimensional stability even at higher temperatures. Moreover, they have superior electrical properties such as dielectric strength, which offer electrical isolation and insulation. They also demonstrate superior bond strength and offer thin, conformal bond lines to improve the integrity of joints altogether.

Polyonics’ XT-657 double-coated flame retardant composite comprises a 1mil polyimide film, which is sandwiched between two high-temperature (less than 150°C) flame retardant acrylic pressure sensitive adhesives (PSAs). The PSAs offer an adhesion strength of ³27 oz/in for 20 minutes of dwell, ³32 oz/in for 24 hours of dwell, and a tack of ³100 gr/in. Different liners are offered, which make the material suitable for most of the die cutting processes.

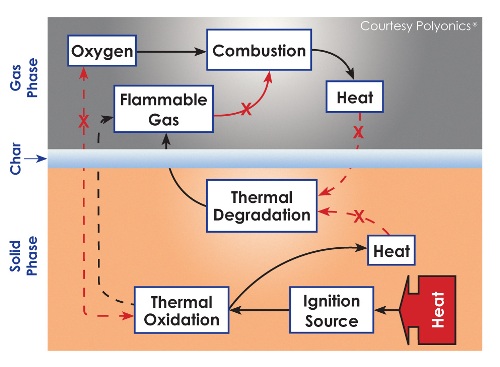

Polyonics’ flame retardant tapes have specially formulated additives and resins that prevent flammable gas emissions and offer dimensional stability to the tape. Moreover, these tapes form a char layer, which functions as a heat protection by decreasing thermal degradation and reducing the thermal oxidation rate, thus preventing the propagation of fire.