Siemens VAI Metals Technologies has partnered with Centro Sviluppo Materiali (CSM) to develop technology packages and production methods for use in processing and rolling of high-quality steel rails.

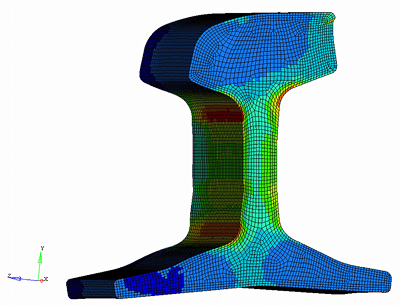

Simulation of stresses in a rail segment with the finite element method.

Simulation of stresses in a rail segment with the finite element method.

Enhancing the overall toughness and surface quality of the rail head are the key objectives of this partnership. During early April, the companies inked the partnership contract spanning initially for a period of two years.

According to Siemens VAI Metals Technologies’ CTO, Andreas Flick, the company will integrate its full-line supplier knowledge of long-product rolling mills together with the extensive experience of CSM in the process development and material research field. The objective of this partnership is to provide customized technology packages that will enable the rail production by rolling mill operators and satisfy the present and upcoming requirements of global rail transport, he added.

High-quality rail surface head is required for the high-speed trains, which are used for long-distance passenger transport. The track bed and rails have to be designed in such a way that they can withstand the high axle loads due to freight traffic and more than 10 t of wheel loads due to rail contact regions. This rail can also withstand high contact stresses and has high wear resistance.

The partnership between CSM and Siemens will initially focus on developing a system for the rail head hardening. The metallurgical features essential for the technology packages and rail head will be manufactured for the treatment and rolling lines in rail rolling mills.