A new method to control the phase of titanium dioxide (TiO2) at room temperature has been developed by a research team from North Carolina State University (NC State). The innovation is expected to make the material more efficient in several applications, including optical communication technologies, smart sensors, antimicrobial coatings, hydrogen production and photovoltaic cells.

A new technique allows researchers to control the phase of the titanium dioxide by modifying the structure of the titanium trioxide and sapphire substrate.

A new technique allows researchers to control the phase of the titanium dioxide by modifying the structure of the titanium trioxide and sapphire substrate.

Commonly, TiO2 is available in one of the two critical phases, called anatase and rutile. The atoms in TiO2 arrange themselves in one of the two phases or crystalline structures and the arrangement demonstrate the material’s electronic, chemical and optical properties. Hence, each phase has different features. The anatase phase is suitable for applications like hydrogen production and can also be used as an antibacterial agent, while the rutile phase is ideal for applications, such as optical communication technologies, smart sensors and photovoltaic cells.

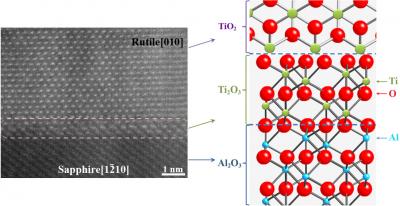

The innovative technique developed by the NC State team precisely controls the phase of TiO2 and stabilizes the phase, preventing the change during temperature fluctuations. This process is referred as phase tuning. In the process, a sapphire substrate with desired crystalline structure is used and a template layer of titanium trioxide (TiO3) is grown over the substrate. The structure of TiO3 is similar to the structure of the substrate. Finally, titanium dioxide is grown on top of the TiO3 layer. The structure of TiO2 is different from that of TiO3 layer. Thus, the titanium dioxide can be created in any phase just by altering the structure of the sapphire substrate and titanium trioxide.

The team has also described how the method can be integrated with computer chip substrates, which can be included in electronic devices such as smart sensors.