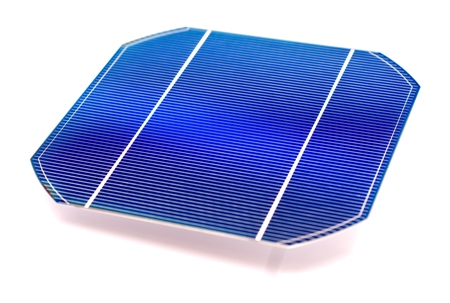

Imec has announced that it is exhibiting a 20.04% large-area industrial-level silicon solar cell at the Intersolar Show, which is being held from 9 to 12 July, 2012 in San Francisco. This high-efficient solar cell is manufactured using a low-cost industrial method.

Imec’s Industrial-level Silicon Solar Cells

Imec’s Industrial-level Silicon Solar Cells

The company’s own PERC method increases the solar cell’s conversion efficiency by optimizing material and structure, while at the same time maintaining cost effective device processing and concepts. The PERC-cell matches with the specifications required for manufacturing industrial photovoltaic cells. This large-area Cz p-type silicon solar cell features Ag-single screen-printed front side contacts, a simple homogeneous emitter, an adapted Al back-side metallization and two busbars. This simple processing may potentially increase efficiency and minimize expenses in industrial production settings. The company is currently transferring this simple method to 156x156 mm² wafers.

Imec processed the silicon solar cells at its new solar cell pre-pilot line. An advanced industrial equipment, worth of €10 million, has been deployed in this pre-pilot line, which has the potential to process solar cell wafers in 156x156 mm² size. A flexible operational approach is carried out at the pilot line to process about several 1,000 wafers per week.

Imec’s Director Photovoltaic Research, Dr. Jef Poortmans stated that the company’s simple PERC cell addresses the needs of the photovoltaic industry to cut down the costs involved in silicon solar cells production. The efficiency of the cells can be increased through the PERC process, which integrates a simple device structure and optimized processing.