Since the utilization of ultraviolet and visible light curable masking resins is ever-increasing, Intertronics has introduced a new masking agent from DYMAX called SpeedMask726-SC.

DYMAX SpeedMask726-SC is formulated to deliver superior surface protection to orthopaedic implants, turbine engine components, and metal components during powder-coating, decorative etching, anodizing, blasting, plasma spray grit, plating processes.

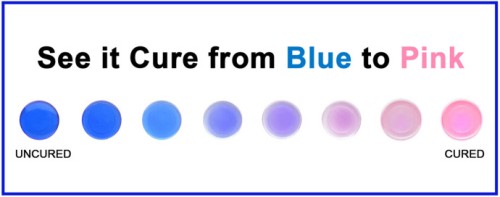

The formulation of DYMAX726-SC is based on the patented See-Cure technology. This masking agent begins with bright blue in color under its uncured state, thus providing easy visibility and confirming the quantity and position of placement. When exposed to adequate light energy, the color transfers from blue to pink, an indication of the completion of the curing process. This confirms visually that the mask has obtained an adequate dose of energy to achieve cure. DYMAX 726-SC is also capable of maintaining flexibility even at higher temperature processes of about 204°C.

SpeedMask 726-SC is suitable for surfaces, including glass, cobalt, titanium, aluminum, stainless steel, steel, and nickel alloys. This masking agent can be applied either by coating, dipping or spraying and can be added easily into automated systems. It enables fast curing and can be removed easily without leaving any residue on the component surface by utilizing a hot water soak. This in turn helps in improving throughput and reducing processing costs.

SpeedMask 726-SC complies with RoHS Directives 2003/11/EC and 2002/95/EC.