Universidad Politécnica de Madrid UPM researchers have obtained a patent for gypsum boards that can store thermal energy, which will bring down up to 40% of a building’s energy consumption. The boards along with strategies like natural airing and sunlight can bring down energy consumption, especially in Spain where nearly 80% of the energy is imported.

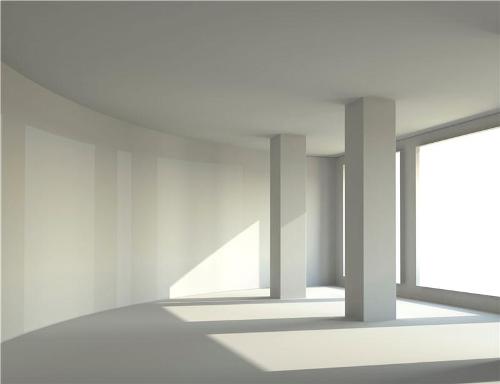

Footer: Picture of a gypsum board with PCMs installed in a room ©UPM

Footer: Picture of a gypsum board with PCMs installed in a room ©UPM

The Department of Building and Architectural Technology conducted the research at the E.T.S of Architecture of the UPM. The research focuses on incorporating phase change materials (PCMs) to the boards. This novel constructive element can store in 1.5 of thickness, five times the thermal energy of a traditional gypsum board having identical thickness. Consequently, this research maintains local temperature at the place of board installation within the 20ºC-30ºC comfort area without requiring air conditioning systems.

In order to develop this novel material, UPM researchers selected plaster due to its availability, cost-effectiveness, increased use in building and easy integration of new additives.

PCMs are substances that release or store thermal energy by latent heat. Presently only 26% of PCMs are incorporated in plastic boards when compared to the 45% possible with the present research. To ensure that there are no issues with gypsum during the liquid phase microencapsulated paraffin by BASF is selected as PCMs. In order to make sure that there are mechanical and physical benefits as well as a high percentage of PCMs in boards, two other additives were added to the mixture, which are fluidizing and fibers.

PCMs, fibers, gypsum and fluidizing were combined by changing the proportions to get a number of compounds. Various combinations were tested to know the physical properties, porosity, workability, setting time and density as well as mechanical properties like strength, hardness and flexibility as well as aesthetics.

The combination of increased PCM percentage around 45% with required regulations was tested thermally.