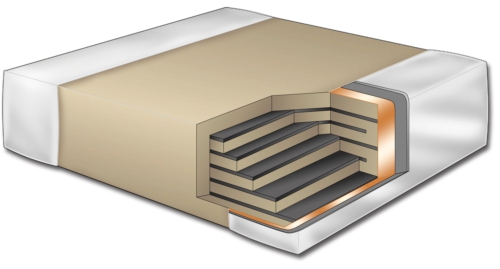

KEMET, a company that manufacturers a range of capacitors such as ceramic, tantalum, film, aluminum, paper and electrolytic capacitors, has unveiled its yet to be patented ArcShield technology used to produce multilayer ceramic capacitor (MLCC) with a X7R dielectric.

KEMET ArcShield High Voltage Mutllayer Ceramic Capacitor

KEMET ArcShield High Voltage Mutllayer Ceramic Capacitor

The MLCC capacitors produced using the new technology is suitable for high voltage applications which are plagued by the problem of arc-over discharge otherwise known as surface arcing. The arc-over discharge is detrimental to the capacitor as well as other components surrounding the capacitor on a printed circuit board.

The ArcShield high voltage MLCCs prevent arc-over discharge and are an economical and more reliable alternative to surface coating technologies normally employed to inhibit surface arcing. The coating given by conventional surface coating technologies are susceptible to damage during the assembling and handling process that leaves the capacitor vulnerable to arc-over discharge that would occur in a device that is sans protective coating.

The surface arcing in MLCCs occur when application voltages reach or exceed 300 V as a result of the voltage potential difference between the termination surfaces of the MLCCs or the voltage gradient between a termination surface and the internal electrode arrangement of the capacitor. The arc-over phenomenon can either cause the dielectric material to breakdown or damage the components in the surrounding area. The ultimate outcome is a short-circuit condition which translates as a disastrous failure of the device.

The ArcShield MLCCs from KEMET are suitable for application as snubbers in lighting and voltage multiplier devices. The capacitors are also available in automotive grade for use in cabin or under-hood applications.