Nov 15 2012

Research published by the National Physical Laboratory (NPL) and the University of Birmingham has won the T P Hoar Prize from the Institute of Corrosion, for the best paper published in Corrosion Science in 2011.

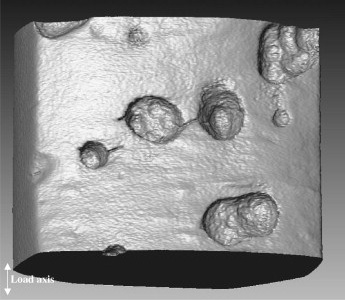

An X-ray tomography image of turbine steel showing corrosion pits and cracks

An X-ray tomography image of turbine steel showing corrosion pits and cracks

The research looked at the problem of crack formation in disc steel used in steam turbines in the power industry. Specifically, a combination of measurement and modelling techniques were carried out to study the transition from a corrosion pit to a stress corrosion crack. The published results demonstrate that, contrary to popular belief, cracks form near to the surface of the steel at the mouth of a corrosion pit rather than at its base.

If a component within a steam turbine fails, it is costly in terms of repair, downtime and potentially lost energy generation. NPL carries out research to characterise the evolution of corrosion damage to these components to develop effective testing methods and framework for life prediction.

In this research a radiography-based technique called X-ray tomography was used to study the pit-to-crack transition process in detail on specimens of a medium strength turbine disc steel. This is a non-destructive technique that allows the interior structure of solid materials to be visualised. The images obtained clearly show that the majority of the cracks form above the base of the pits.

Finite element analysis was then used to model the stress and strain around a corrosion pit. This demonstrated that localised plastic strain occurs just below the pit mouth, explaining the observed crack formation.

This improved understanding of how cracks form under certain conditions is vital when assessing the lifetime of components within steam turbines and that of power plants in general. It will also help when designing and choosing materials for a new generation of more energy efficient and cost-effective power plants.