The tungsten alloy DENSIMET® reliably shields against X-rays and gamma radiation. With its new production process and great expertise in the materials field, PLANSEE has made the manufacture of DENSIMET® shielding components particularly cost-effective.

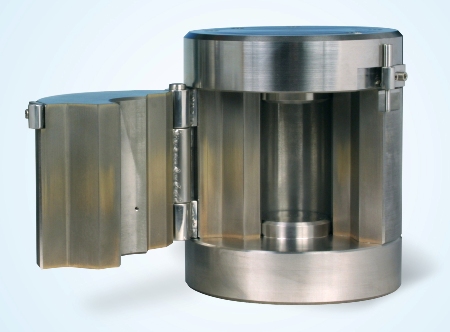

Densimet Container

Densimet Container

Whether in the world of medical or industrial X-ray technology, radiotherapy or nuclear power stations: Wherever high-energy radiation is used, it is vital to protect people against it.

The denser the material, the better able it is to protect from radiation. That is why heavy elements absorb X-rays and gamma radiation particularly well. Lead is still the most frequently used shielding material. Because it is a very soft material, it is mostly used only in combination with support structures made of steel.

Lead is a toxic material that is harmful to the environment and humans. The onerous recycling process makes lead expensive despite the low initial procurement costs. Many enterprises are therefore looking for a suitable alternative for providing reliable radiation protection.

DENSIMET®combines shielding properties with excellent machinability

The density of tungsten is 60 percent higher than that of lead. That is why even thinner layers of tungsten are able to provide reliable shielding against radiation.

The tungsten alloy DENSIMET® is particularly suitable as a shielding material. It consists of tungsten and a small proportion of nickel-iron. Like tungsten, the material has excellent shielding properties. However, it is also considerably more ductile than tungsten and can therefore be machined better.

Thanks to the ductility and high melting point of the material, isotope containers made from DENSIMET® are also able to withstand extreme mechanical and thermal loads.

Because of their high strength, DENSIMET® components act as both the support structure and the shielding in one. Unlike when lead is used, no additional steel support structures are required.

New manufacturing process cuts costs

DENSIMET® is usually pressed, sintered and subjected to various forming operations in order to produce sheets or ribbons. During the manufacture of thin sheets or foils, the material is rolled several times. This makes production expensive.

Thanks to a new manufacturing process designed specifically for foils and thin sheets, the materials expert PLANSEE has been able to reduce production costs significantly.

And the new manufacturing process has another advantage. The material's microstructure is isotropic - i.e. it has no characteristic orientation. As a result, DENSIMET® sheets can be bended particularly well to form complex shapes.

The material has a uniform density distribution and no porosity.

PLANSEE supplies tungsten alloy with long service life

Also foils and sheets made from polymers with a tungsten content are used to shield against X-ray radiation. Due to their organic components, these polymer composites age when exposed to X-ray radiation. PLANSEE's fully metallic DENSIMET® offers a longer service life than can be achieved using this type of material.

However, it is not just in shielding applications that DENSIMET® represents a better alternative than lead. In tailor-made components for medical technology, DENSIMETv provides reliable shielding against X-rays and gamma radiation. When used in collimators, it reduces scattered radiation in the detectors present in computer tomographs. When used for balancing weights and vibration dampers in motors and drive components, this tungsten alloy is able to withstand extreme stresses.

PLANSEE High Performance Materials

The Plansee Group is a leading enterprise in the field of powder metallurgy and covers the entire production process from the ore right through to the customer-specific component.

The PLANSEE High Performance Materials division is an expert in the field of molybdenum, tungsten, tantalum, niobium and chromium components. Whether in electronic applications, medical technology or high-temperature furnaces: When conventional metals come up against their limits, PLANSEE's alloys and composites take over.