The challenges of GaN growth on Si(111), especially for LED growth, are well known and meanwhile controllable.

Cooldown-assisted layer cracking as a result of high tensile stress can be prevented and crystal quality can be enhanced by sophisticated interlayers. Numerous institutions worldwide are already using LayTec‘s EpiCurve® TT with advanced curvature resolution for high quality GaN devices on large scale Silicon substrates.

Now, this experience is being transferred to growth on Si(001) and Si(110), because GaN based power electronics can be easily integrated with Si standard electronics (CMOS) and is available in large sizes up to 300 mm.

At the International Workshop on Nitride Semiconductors (Japan, October 2012), Jonas Hennig of Otto-von-Guericke Universität Magdeburg (Germany) reported about high performance of GaN HEMT structures on Si(001) with highly optimized interlayers to control stress and defect density [1].

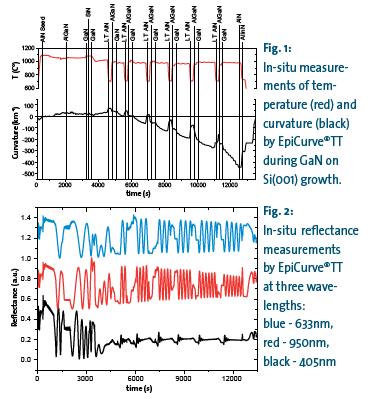

According to Mr. Hennig, in-situ growth monitoring by Epi- Curve® TT is a great help for their strain engineering. Fig. 1 shows temperature (red) and advanced resolution curvature (black) measurements, Fig. 2 - reflectance measurements at three wavelengths. The well pronounced Fabry-Perot oscillations at 633 nm (blue) and 950 nm (red) in correlation with the smooth development of the curvature show the high quality of the GaN. Furthermore, during the growth of interlayers, when the temperature is being brought down, an abrubt increase of curvature can be observed (Fig. 1).

The three combined reflectance signals help to determine the growth rates and adjust the growth parameters. Additionally, the 405 nm reflectance (Fig. 2 - black) provides information on the structural interface quality.

The work at Otto-von-Guericke University and other institution which use LayTec‘s in-situ tools for Silicon applications shows that the quality of GaN/Si can be significantly improved by advanced curvature monitoring in combination with multiple wavelength reflectance. LayTec is proud to be a part of the technology transfer from Si(111) in LED growth to Si(001) and Si(110) in power electronics.