MicroSense, LLC, a worldwide leader in high sensitivity vibrating sample magnetometers (VSMs), magnetic metrology systems, high resolution capacitive sensors, and wafer metrology systems, today announced that it has booked and shipped multiple customer orders for its next generation "EZ" series VSM magnetic metrology systems from global customers. These VSM metrology systems are used to characterize the magnetic properties of magnetic thin films or any liquid or solid.

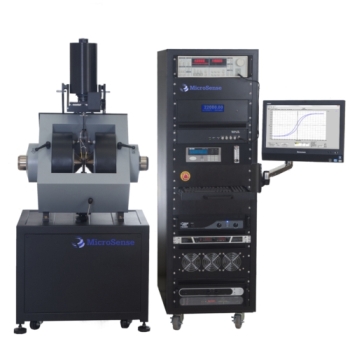

New EZ series Vibrating Sample Magnetometers from MicroSense, used to characterize the magnetic properties of magnetic thin films or any liquid or solid, offer exceptional field control resulting in faster measurements with improved sensitivity. (PRNewsFoto/MicroSense, LLC)

New EZ series Vibrating Sample Magnetometers from MicroSense, used to characterize the magnetic properties of magnetic thin films or any liquid or solid, offer exceptional field control resulting in faster measurements with improved sensitivity. (PRNewsFoto/MicroSense, LLC)

"We are pleased to announce receiving multiple orders and shipping our next generation "EZ" series VSM," said Tom McNabb , President and COO of MicroSense. "With 30 years of VSM experience, we continually strive to improve our metrology system performance in providing value to our global customers. MicroSense is the only company to offer both VSM systems for R&D, and also magnetic metrology systems for production environments."

"The EZ series VSM systems offer exceptional field control resulting in faster measurements with improved sensitivity. The signal to noise ratio for a typical magnetic measurement at temperature is at least 5 times better than what is offered by our competitors," according to Erik Samwel , Ph.D., Director of VSM Business at MicroSense. "Compared to our previous generation VSM's, these new systems offer improved performance, a smaller footprint, and a more contemporary design."

About MicroSense, LLC

MicroSense is a leading manufacturer of magnetic metrology systems and Vibrating Sample Magnetometers (VSM), which are utilized in high resolution metrology applications, such as hard disk drive disks & read/write head wafers, semiconductor MRAM wafers, and fundamental magnetic material characterization. Leading data storage and semiconductor equipment manufacturers, as well as universities and research institutes around the world have used and trusted magnetic metrology systems from MicroSense for over 30 years.

MicroSense also offers an extensive line of patented capacitive sensors used to make very precise, high bandwidth measurements of precision products such as solar wafers, hard disk drive motors, air bearing spindles, precision X-Y stages, automotive parts and machine tools. Leading equipment manufacturers around the world use MicroSense capacitive sensors in wafer lithography systems, solar wafer sorters, autofocus mechanisms, nanopositioning stages, metrology systems and flat panel display manufacturing equipment.