Dispensing specialists Intertronics, together with their sales partners Liquidyn, are now addressing those applications where very precise non-contact micro dot dispensing is required, in the range of 3 – 200 nl, e.g. for oil, grease, adhesive, silicone, paint, flux, medical products, and many other materials typically used in electronics, automotive, packaging, medical, cosmetics, pharmaceutical and food industries – even filled materials.

The advantages of the Liquidyn P-Dot system were described by Peter Swanson, MD at Intertronics: “In the course of miniaturisation in almost all technical fields, demands on the abilities of dispensing systems have been increasing. The smallest amounts of adhesives, oils and greases and other fluids require pin point precision in dispensing, in combination with the shortest takt times. In the P-Dot system Liquidyn has developed a pneumatically operated high performance valve for non-contacting dispensing of adhesives and other media which will deliver the smallest amounts of a medium with a high degree of reliability and precision.”

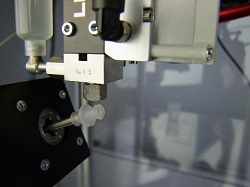

The P-Dot valve can dispense dots, beads and lines of medium to high viscous chemicals, as well as filled products with the size of the dispensing droplets adjustable from 0.3mm to 5mm in diameter at rates of up to 150 times per second, which allows reduced cycle times and increased output and productivity. Able to dispense from up to 10mm away, process issues due to parts and/or fixture tolerances can be solved by using this contactless dispensing technology.

For further information please see http://www.intertronics.co.uk/liquidyn_jetting_valves or visit their blog at www.adhere.uk.com – also see www.youtube.com/intertronicsadhere.