Uniqsis Ltd. has demonstrated how its proprietary glass static mixer-reactor chip technology can be used to perform highly exothermic reactions more conveniently at higher temperatures with useful throughputs under continuous flow-through conditions.

To achieve high reproducibility and facilitate scale up, it is important to control both mixing and temperature, particularly for highly exothermic or rapid mixing-dependent reactions (‘Type A’ reactions).

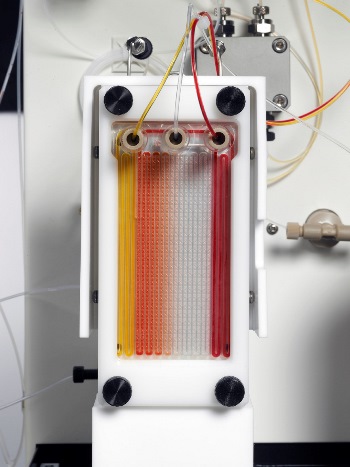

Where the diffusional mixing provided by simple ‘T’-piece mixers is too slow to afford good control and reproducible reaction outcomes, Uniqsis has introduced a range of ingenious glass static mixer blocks ('chips') that incorporate channels with active mixing geometries to provide efficient turbulent mixing throughout the reaction vessel whilst also functioning as very efficient heat exchangers.

Glass static mixer-reactor chip technology.

Glass static mixer-reactor chip technology.

Uniqsis offers both conventional 2 input 1 output static glass mixer/reactor chips for combining 2 reagent streams, useful in nitration chemistry for example, and a 3 input 1 output chip which is particularly useful for reactions requiring a ‘quench’ input. The chips are easy to incorporate into the reaction flow path and use conventional threaded connectors that require no tools to attach and achieve leak-free seals over a wide temperature range. Precision machined from chemically inert borosilicate glass, these chip are tested to operate efficiently at up to 40 bar pressure and from -80°C to +150°C.

Metalations are typically performed at very low temperature (often -78°C) in batch with slow addition of the organometallic base in order to control the highly exothermic nature of such reactions. In Application Note 25** - Uniqsis demonstrate how a low temperature metalation-quench reaction can be performed at higher temperature in flow using the mixer-reactor chip in combination with a FlowSyn Cold Coil is able to reproducibly perform a high yield metalation-quench reaction.

Uniqsis mixer-reactor chips in combination with a FlowSyn column module, Cold Coil or Polar Bear reaction station offer a convenient and reliable solution to the control of mixing and temperature in chemical synthesis.

Uniqsis specialises in the design of meso-scale continuous flow chemistry systems for a wide range of applications in chemical and pharmaceutical research. The company’s aim is to make flow chemistry easily accessible to both novices and experienced users.