Jun 17 2013

A research group headed by Dr. Tokuyuki Teraji, a Senior Researcher in the NIMS Optical and Electronic Materials Unit, developed a novel synthesis technique which dramatically increases the source material utilization rate in the diamond chemical vapor deposition (CVD).

Abstract

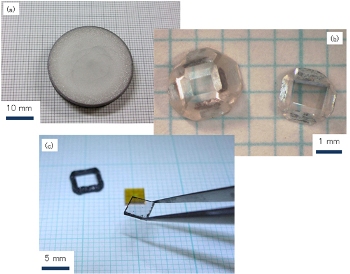

Isotopically-enriched diamond crystals obtained by the new synthesis technique. (a) CVD polycrystalline diamond: (b) HPHT single crystal diamond (c) CVD single crystal diamond

Isotopically-enriched diamond crystals obtained by the new synthesis technique. (a) CVD polycrystalline diamond: (b) HPHT single crystal diamond (c) CVD single crystal diamond

A research group headed by Dr. Tokuyuki Teraji, a Senior Researcher in the Optical and Electronic Materials Unit (Unit Director: Naoki Ohashi) of the National Institute for Materials Science (President: Sukekatsu Ushioda), developed a novel synthesis technique which dramatically increases the source material utilization rate in the diamond chemical vapor deposition (CVD). The group applied this new technique to synthesis of diamond crystals which were isotopically-enriched with mass number 12 carbon (12C), and succeeded in synthesizing a diamond bulk single crystal with the world's highest 12C isotopic ratio.

When high purity diamond is synthesized by the CVD process, methane gas is generally used as the source gas. Normally, at most 1% of the supplied methane gas is converted to diamond, and 99% or more of the methane gas is emitted to the atmosphere before utilizing for diamond synthesis. Due to this low material utilization rate, it had been difficult from the viewpoint of cost to use expensive gas in bulk crystal synthesis, as the conventional process consumed a large amount of source gas. In the newly-developed CVD diamond synthesis technique, the utilization rate of the methane source gas was dramatically improved by supplying the gas under conditions greatly different from those in the conventional process. As a result, an extremely high gas utilization rate of 80% was realized when synthesizing polycrystalline diamond.

The development of this CVD synthesis technique with a high gas utilization rate makes it possible to synthesize diamond using extremely expensive isotopically-enriched methane as the source gas. As a result, the NIMS group succeeded in obtaining diamond bulk single crystals with the world's highest 12C isotopic ratio of 99.998% (isotopic ratio of 13C: 0.002%). Single crystal diamond with a 12C isotopic ratio of 99.995% was then obtained by using the polycrystalline diamond produced by this technique (isotopic ratio of 12C: 99.998%) as a solid source material for diamond synthesis by the high pressure/high temperature (HPHT) process, which requires a solid source material. Because 12C enriched methane gas, etc. is generally supplied as a source gas, this CVD technique, which greatly improves the methane source gas utilization rate, is essential for obtaining 12C solid carbon material for use in HPHT synthesis.

Various applications, such as use in high performance heat sinks, etc., are expected with 12C enriched diamond, which has higher thermal conductivity than diamond having a natural 12C ratio of 98.9% (13C: 1.1%). Moreover, as it is known that the coherent time of electronic spin becomes longer in 12C enriched diamond crystals, accelerated development aiming at high performance quantum information communication devices using diamond is also expected.

Portions of this research were carried out with financial support from the Grant-in-Aid for Scientific Research (Basic Research) program of the Japan Society for the Promotion of Science (JSPS) and as part of the Japan-Germany Research Exchange Project under the Strategic International Collaborative Research Program (Strategic International Research Cooperative Program) of the Japan Science and Technology Agency (JST).

These research results were announced in the online bulletin of the scientific journal "Applied Physics Express" on April 15, 2013 (Japan time).