3D Systems announced today that it has closed its acquisition of Phenix Systems, a leading global provider of Direct Metal Selective Laser Sintering 3D Printers based in Riom, France. The company paid $15.1 million for 81% of the share capital and will immediately launch a simplified take-over bid process in accordance with the French Markets Authority on the remaining shares and voting rights.

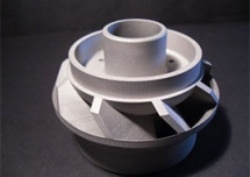

Phenix Systems designs and manufactures proprietary Direct Metal 3D Printers that print chemically pure, fully dense metal and ceramic parts from very fine powders with the granularity of 6 to 9 microns. Materials include stainless steel, tool steel, super alloys, non-ferrous alloys, precious metals and alumina for a variety of aerospace, automotive and patient specific medical device applications. Phenix Systems strengthens 3D Systems offerings and immediately positions it at the heart of these rapidly growing direct manufacturing opportunities.

“Phenix Systems is a strategic and differentiated addition to our extensive 3D content-to-print portfolio and we are thrilled to deliver these powerful solutions to our customers,” said Avi Reichental, President and CEO, 3D Systems. “Our proven track record in advanced manufacturing, combined with Phenix Systems extensive metals technology and expertise represents a true game-changer that empowers our customers to manufacture the future.”

Learn how Phenix direct metal solutions can help you at 3DSystems.com.

About 3D Systems Corporation

3D Systems is a leading provider of 3D content-to-print solutions including 3D printers, print materials and on-demand custom parts services for professionals and consumers alike. The company also provides CAD, reverse engineering and inspection software tools and consumer 3D printers, apps and services. Its expertly integrated solutions replace and complement traditional methods and reduce the time and cost of designing new products by printing real parts directly from digital input. These solutions are used to rapidly design, create, communicate, prototype or produce real parts, empowering customers to manufacture the future.